Subscribe now to get notified about IU Jharkhand journal updates!

Role of Supplier Relationship Practices (SRP) On Organizational Performance: A Dairy Industry Study

Abstract :

In supply chain management strategies, supplier relationship management activities play an important role. A successful strategic alliance and integrated relationship with a supplier is very much needed. It should be revolved around trust, loyalty, positive-sum game (a win-win relationship), cross-functional team, achieving common goals and collaboration. Supplier Relationship Practices (SRP) entails creating closer and more collaborative relationship with key suppliers in order to uncover and realize the new value and reduce risk. Relationship quality can represent a competitive advantage for dairy supply chains and should, therefore, be improved using tools of supplier relationship management.

The research paper attempts to find out the relationship between the supplier relationship management (SRP) practices and organizational performance of Indian dairy industry. Various practices of SRP through extensive literature review are taken into account for establishing the relationship with organizational performance. Multiple regression analysis was performed on the dairy plant (DP), milk cooperative (MC) and milk retailer (MR) questionnaire in order to find out the impact or role of adopted SRP practices on organizational performance matrix.

Keywords :

Suppler Relationship Management (SRP), Supply Chain Management (SCM), Organizational Performance, Indian Dairy IndustrySupply Chain Management Practices with reference to Dairy Industry of India

Milk supply chains are more concerned with controlling of milk quality and supply fluctuations which are unique to this sector. Perishable goods like milk require a time efficient supply chain. This perishable factor can affect the milk supply chain. Supply chain management has seen as a source of gaining competitive advantage in the business world. Due to pressures from increased competition resulting from globalization of supply, processing and distribution networks, high levels of service expectations and competitive pricing, the supply chain management has become more important in recent years. For the success of a dairy industry, efficient supply chain management is a pre-requisite. Thus, the supply chain performance of the processing units is a deciding factor for the success of the unit. The Indian supply chain for milk products is affected by abnormal wastage and poor handling. The wastage occurs because of multiple points of handling. Shortage of cold storage facilities and refrigerated transport equipment lead to inefficiencies in handling milk products. There is a compelling requirement for appropriate infrastructure for storage and transportation such as temperature controlled warehouses and vans. By practicing improved supply chain management practices, there will be a significant reduction in the wastages of milk and milk products which in turn will benefit both the farmers as well as the consumers by means of increased returns and decrease in price respectively. Supply chain management (SCM) over past two decades had played an important role on emphasizing the interdependence of buyer and supplier firms working collaboratively to improve the performance of the entire supply which has generated huge significance in both academic and industry. In particular, with the increasing trend of business globalization, how a firm gains and retains its competitive advantage while facing domestic and international challenges has drawn a lot of attention (Huo et al., 2008; Kannan and Tan, 2005). SCM provides benefits to suppliers and customers by enhancing upstream and downstream linkages. Additionally, firms have begun to integrate their external customer-firm-supplier relationships and internal contextual factors as a mean to improve customer satisfaction, firm performance, and firm competitiveness (Ou et al, 2010). SCM has been recognized as an important issue and has generated a substantial amount of interest among managers and researchers. Since the 1980s, SCM has been regarded as one of the most effective ways for firms to improve their competitive advantage. SCM has been documented to be positively associated with enhanced competitiveness and improved firm performance (Li et al., 2006). In addition, SCM has been widely considered to be an effective management tool for firms to maintain business stability, growth, and prosperity. Supporting this claim, Harrison and New (2002) in his report show 70 percent of the respondents thought that their supply chain strategy was currently important in achieving competitive advantage and in the future 91 percent thought that this would be the case and in the same context Indian dairy industry has been dramatically increasing towards supply chain management because of recent years certain significant changes that are affecting the industry. The rapid development of globalization, shifting consumer demand, dismantling state support schemes and technological progress has so caused a declaration of industrialization of the dairy industry. Various literature shows that there are various SCM practices which have a significant role in the dairy industry in recent years because of noteworthy changes which are taking place in the market environment. Effective supply chain management (SCM) has become a potentially valuable way of securing competitive advantage and improving organizational performance since competition is no longer between organizations but among supply chains. In fact, firms no longer competitively can survive in isolation of their suppliers, customers and other entities of the supply chain. Additionally, SCM also improves market responsiveness, reduction in logistics cost, added economic value and optimum utilization of capital cost. Substantially, SCM has been considered one of the critical areas in the development of dairy industry to meet the global market demand.

Role of Supplier Relationship Practices (SRP) on Indian Dairy Industry

Supplier Relationship Practices (SRP) entails creating closer and more collaborative relationship with key suppliers in order to uncover and realize the new value and reduce risk. Relationship quality can represent a competitive advantage for agri-food supply chains and should, therefore, be improved using tools of supplier relationship management. Milk buyers can build a loyal base with their suppliers as a mean to secure uninterrupted milk-supplies. One of the major efforts which should be made is that milk buyers are encouraged to use collaborative communication with their suppliers by having frequent communication, proper feedback and adequate information sharing with their supplier which encourages problem-solving and avoids misunderstandings in their relationships. In supply chain management strategies, supplier relationship management activities play an important role (Wisner, 2003). Long-term relationship refers to the intention that the arrangement is not going to be temporary (Chen and Paulraj, 2008). A successful strategic alliance and integrated relationship with a supplier are very much needed. It should be revolved around trust, loyalty, positive-sum game (a win-win relationship), cross-functional team, achieving common goals and collaboration (Chandra and Kumar, 2000). A firm success is linked to the strength of its relationship with supply chain partners and it could reduce and increase revenue (Spekman, Kamauff, and Myhr, 1998). In the today competitive business environment, companies are relying on their supply chain as a source of competitive advantage. Purchasing and supply chain management has achieved a higher level of importance. So for this purpose, there is greater dependence on the supplier. Supplier relationship management (SRP) has played a strategic role in the organization, and have significantly engaged in creating a competitive advantage and their action has a positive impact on organizational performance (Jabbour and Jabbour, 2009). Closer long-term relationships with suppliers imply the use of joint quality planning (e.g. forming of quality requirements and product specifications, use of quality control, etc.) and joint production planning (e.g. use of JIT system) between buyer and supplier (Maloni and Benton, 1997; Monczka et al., 1995). Suppliers are increasingly viewed as partners. They become more deeply involved in co-operative problem solving, in new product development and in workgroups with buyer’s representatives in order to identify areas of improvement (Harland et al., 1999; Stuart and McCutcheon, 2000; Shin et al., 2000; Ragatz et al., 1997; Wynstra and Pierick, 2000; Stanley and Wisner, 2001). The main purpose of close, long-term relationships with suppliers is the achievement of high-quality products and services that satisfy customer needs. Often, suppliers lack the abilities and competencies required to deal with the high-quality standards required by their buyers. Therefore, supplier development is necessary. Supplier development activities vary widely and they may include raising performance expectations, education and training on quality requirements and know-how for supplier personnel, recognition of supplier’s achievements and performance in the form of rewards, placement of engineering and other buyer personnel at the supplier’s premises and direct capital investment by the buying firm in the supplier (Krause and Ellram, 1997; Monczka et al., 1998). The relationship with the supplier is considered to be a partnership and is valuable to the firm (buyer) as it can be a source of competitive advantage. Various previous researches show that the ultimate success or failure of a supply chain alliance is determined by the level of commitment, trust, and cooperation of its members (Monczka et al., 1998; Handfield et al, 2002; Walter et al., 2003). Thus, each part must be aware of other part’s needs and should align its expectations and goals with its partners’ expectations and goals (Stuart and McCutcheon, 2000; Spekman et al., 1998).

Research Methodology

Research Problem

Indian dairy industry has played a prominent role in strengthening India’s rural economy. It has been recognized as an instrument to bring about socio-economic transformation. The white revolution has transformed India’s dairy industry. It has increased the availability of milk as well as providing a reliable source of income and employment to millions of rural families. India has the distinction of being the largest producer of milk in the world for which the credit goes to operation flood program that has linked rural farmers to urban cities. Keeping pace with the country's increasing demand for milk and milk products, the industry has been growing rapidly. It has been seen that Indian dairy industry comes a long way over the years from a milk production of 55.7 MT in 1991-92 to 135 million tons by 2015 and it is estimated to reach180 million tons by 2021-22. Presently, the Indian dairy market is growing at an annual rate of 7 percent. Despite the increase in production, a demand-supply gap has become imminent in the dairy industry due to the changing consumption habits, dynamic demographic patterns, and the rapid urbanization of rural India. It means that there is an urgent need for the higher growth rate of the dairy sector to match the rapidly growing Indian economy. Despite being one of the largest milk producing countries in the world, India accounts for a negligible share in the worldwide dairy trade. So, in order to retain and sustain in a highly competitive business environment of global dairy industry, companies are now trying to improve their organizational performance and achieve competitive advantage. The entire competition in dairy industry revolves around two prominent factors i.e., quality and availability. Quality and availability of dairy products become crucial due to the high degree of product perishability, which requires altogether a different kind of supply chain commonly known as Cold Chain. So the research problem of the research is basically revolved around the supplier relationship practices of the dairy industry. In nutshell, the problem of research lies in the optimization of the dairy industries supply chain so as to meet the future domestic requirements and remain competitive in global markets. The present research study tried to find the actual happenings and accordingly analyze the mechanism for betterment in those processes so as to create a win-win situation for all the stakeholders of the dairy supply chain.

Research Question

How to manage and strategize the supplier relationship practices (SRP) in a way that the Indian dairy industry improves its performance and achieves competitive advantage?

Objectives of the Study

The objectives of the study are derived from the research problem. The objectives of the study are listed as:

- To critically analyze the impact of adopted supplier relationship practices (SRP) on the organization’s performance.

- To suggest a roadmap for improving the performance of the Indian dairy industry through supplier relationship practices (SRP).

Research Hypotheses

Research Design

The proposed research is a kind of exploratory study aimed at finding out the nitty-gritty of the Indian dairy supply chain management, followed by a descriptive research design which helps in evaluating the impact of supplier relationship practices (SRP) on the dairy industry.

Sampling of the Indian Dairy Industry

Supply chain in the Indian dairy industry start from milk production, which is brought about by large scale, medium scale and small or marginal farmers and executed by various milk cooperative societies; from there, milk moves to the dairy processing plants where storing, chilling, processing, packaging, and transportation are done under the supervision of the plant manager and after that processed milk and milk products are distributed and marketed to various milk retail outlets, supermarkets etc. from where they reach to the end consumers. So, keeping that in mind the research is being carried out with three identified group of respondents, who are basically the supply chain members of the dairy industry.

- Milk Processing Unit (Chilling, Processing, Packaging and Transportation)

- Milk collection center (Milk Cooperative Societies, Contractors of Private Dairies)

- Retailers (Marketing and Distribution)

Population

Population means the aggregate of all the elements sharing some common set of characteristics that comprises the universe for the purpose of the research problem. The proposed research covers three groups of respondent which are given below:

- First group of respondents (Milk Processing Unit) – All milk processing units operating in UP and New Delhi-NCR.

- Second group of respondents (Milk Collection Centre) -- All milk collecting centers situated in UP and New Delhi-NCR.

- Third group of respondents (Retailers) -- All the retailers selling milk and milk products in UP and New Delhi-NCR.

Sample Frame

It is the representation of the elements of the target population and consists of a list or set of directions for identifying the target population. The sample frame of the research is identified as:

- First group of respondents (Milk Processing Unit) -- All registered milk processing units situated in UP and New Delhi-NCR i.e. 59.

- Second group of respondents (Milk Collection Centre) -- All associated milk collection centers with registered milk processing units in UP and New Delhi-NCR.

- Third group of respondents (Retailers) -- All associated retailers with registered milk processing units in UP and New Delhi-NCR.

Sample Units

The sample units of the research are as follows:

- First group of respondents (Milk Processing Unit) – Individual registered milk processing unit.

- Second group of respondents (Milk Collection Centre) -- Individual milk collection center associated with a registered milk processing unit.

- Third group of respondents (Retailers) -- Individual milk retail store owner.

Sampling Techniques & Size of Sample

- First group of respondents (Milk Processing Unit) – Judgmental sampling based on the market position of the organization and plant production capacity (i.e. one lakh liter per day), has been being opted for to select the various milk processing units. Ten dairy plants have been taken and from each dairy plant, three respondents i.e., head of the dairy company, operations head, and marketing head were targeted for the study, which renders the sample size to be thirty respondent.

- Second group of respondents (Milk Collection Centre) -- Simple Random Sampling has been used on the provided list of milk collection centers associated with the selected milk processing unit. Randomly, five milk cooperative units have been selected from each milk processing unit, which turned out to be fifty milk cooperatives.

- Third group of respondents (Retailers) – Simple random sampling has been being used to select retail outlets from each selected milk processing unit. Ten milk retail outlets have been selected from each milk processing unit, which turned out to be a hundred milk retail outlets.

Primary Data Sources

Primary data is collected through survey method using structures questionnaire for all four respondents i.e. 10 dairy companies operating in UP and New Delhi-NCR region, and from each dairy plant 3 respondents were taken i.e. head of the dairy plant, marketing head of dairy plant and operation head of the dairy plant, so total sample size is 30. 50 milk cooperative societies which are associated with dairy companies, 100 milk retailers associated with dairy companies and 1000 customers who are consuming milk and milk products.

Structure of Questionnaire

The study used various variables. A variable is something that changes. It changes according to different factors. Some variables change easily while other variables are almost constant. A study often seeks to measure variables. The variable can be a number, a name, or anything where the value can change. The study defines variables according to objectives. As per my research sample plan, there are four respondents for which four structured questionnaires have been developed which needed to be different for a different group of respondents. The three categories of respondents are given below.

- Milk Processing Units

- Milk Collection Centers

- Retailers

Pre-testing and Administering the Questionnaire

The researcher pre-tested the questionnaire by administering it to experts in academics and dairy industry. The academicians were senior professors of the Institute of Agricultural Sciences, BHU (especially the dairy department), Institute of Management Studies-BHU and managers who work in dairies companies such as Parag Dairy etc. The questionnaire was ‘self-administered’ to the respondents.

Measurement and Scaling Design

‘Measurement’ means assigning numbers or other symbols to characteristics of objects, according to certain pre-specified rules. The most important aspect of measurement is the specification of rules for assigning numbers to characteristics (Malhotra, 2007).

For Dairy Plant, Milk Cooperative and Milk Retailer

Primarily, two types of scale were used as agreement continuum and adoption continuum (on five point Likert type scale) for the three respondents’ i.e. dairy plant, milk cooperative and milk retailer, which help in assessing the response of the respondents such as:

- Agreement continuum for measuring agreement level of these three respondents for the concerned practices

- Adoption continuum for measuring adoption level of these three respondents for the concerned practices

Agreement continuum

1= Strongly Disagree, 2= Disagree, 3= Indifferent, 4= Agree, 5= Strongly Agree

Adoption continuum

1= Will not adopt at all, 2= Not adopted, 3= Indecisive for adoption, 4= partly adopted, 5= Fully adopted

Besides that, a few questions were are on the dichotomous scale.

Validity and Reliability

The reliability of this study was checked by the internal consistency method. Internal consistency estimates reliability by grouping the questions in a questionnaire that measure the same concept. One common way of computing correlation values among the questions on the instruments is by using Cronbach’s Alpha.

The content validity of the instrument is the extent to which it provides adequate coverage of the investigative questions guiding the study. A good way to check content validity is to use a panel of persons to judge how well the instrument meets the standards (Cooper & Schindler, 2006). The validity of the instrument was checked by administering it to various experts in the academia and industry during pre-testing.

Data Analysis Design

Multiple regression analysis was performed on dairy plant (DP), milk cooperative (MC) and milk retailer (MR) questionnaire in order to find out the impact or role of adopted SRP practices on organizational performance matrix.

Cronbach’s alpha for dairy plant (DP), milk cooperative (MC) and milk retailer (MR) Questionnaire was calculated as .827, 0.831 and 0.826 respectively. The values were more than 0.6 showing a high correlation, indication scale is having high reliability.

Multiple Regression Analysis

[On Dairy Plant Employee’s Opinion on Performance Metrics]

Multiple regression analysis, in stepwise selection mode, was carried out to identify key predictors for dependent variables, using SPSS 16.0

software. Predictor variables for the analysis were as per the questions of the questionnaire for respondents. Dependent variables were the question

statements in the performance metrics of the questionnaire. Based on multiple regression model summaries, inferences about predictors were deduced

for each of the dependent variables.

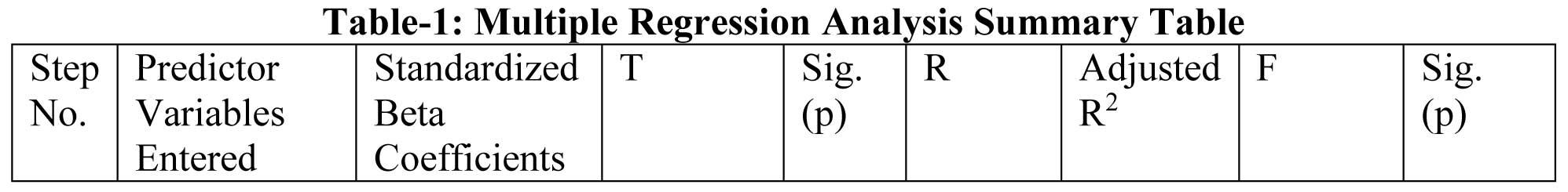

Summary of Multiple Regression Analysis of the dependent variable, “Level of Supplier’s Defect Free Deliveries” is given in Table 1.

For dependent variable ‘Level of supplier’s defect-free deliveries’, one significant predictor variables was found i.e. supplier relationship practices (SRP), (F=22.391, p=0.000). The variable has a positive significant correlation with the dependent variable.

At step I, supplier relationship practices (SRP), entered into the regression analysis. The value of adjusted R2 (=.424) indicated that the maximum amount of various in response to queries was attributable to supplier relationship practices (SRP).

Standardized Beta coefficients, .667 (p=.000) for the one predictor variable, of multiple regression analysis indicated that one unit increase in the supplier relationship practices (SRP) was likely to significantly increase the mean value of dependent variable, distribution cost, by.667 unit

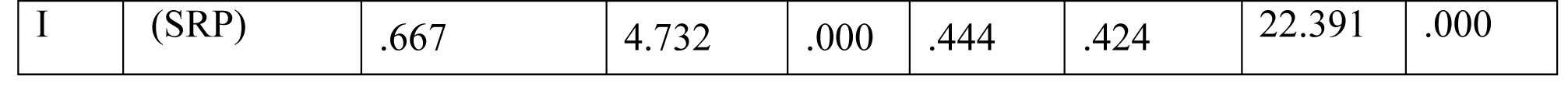

Summary of Multiple Regression Analysis of the dependent variable, “On Time Delivery” is given in Table 2.

For dependent variable ‘on time delivery’, one significant predictor variable was found i.e. supplier relationship practices (SRP), (F=18.958, p=0.000). The variable has a positive significant correlation with the dependent variable.

At step I, supplier relationship practices (SRP), entered into the regression analysis. The value of adjusted R2 (=.630) indicated that the maximum amount of various in response to queries was attributable to supplier relationship practices (SRP).

Standardized Beta coefficients, .802 (p=.000), for the one predictor variables, of multiple regression analysis indicated that one unit increase in the Supplier relationship practices (SRP)was likely to significantly increase the mean value of dependent variable, on time delivery, by.802 unit.

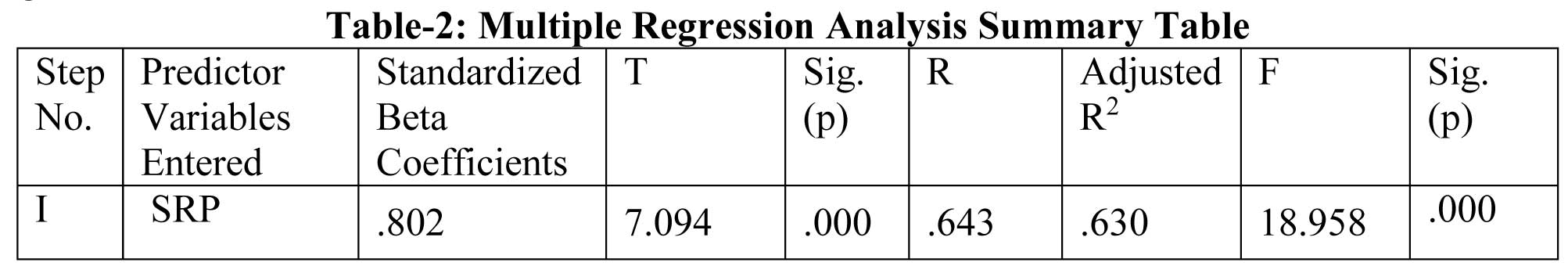

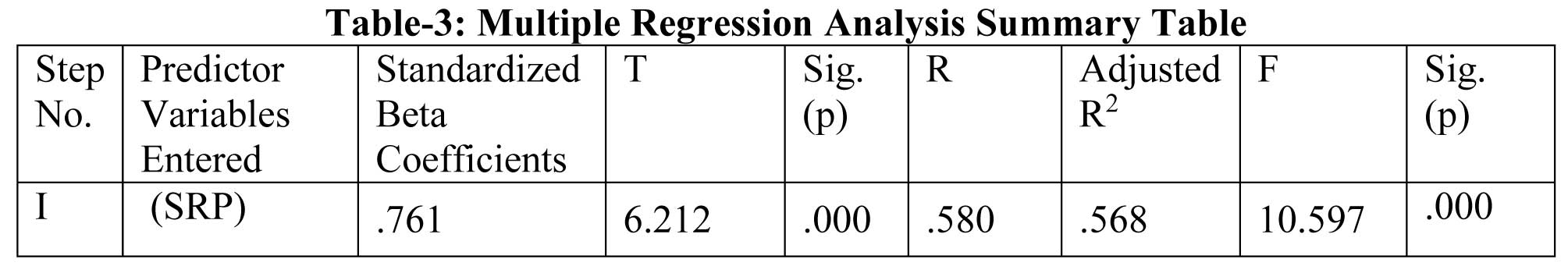

Summary of Multiple Regression Analysis of the dependent variable, “Backorder Rate” is given in Table 3.

For dependent variable ‘backorder rate’, one significant predictor variables was found; SRP, and (F=10.597, p=0.000). These variables had a positive significant correlation with the dependent variable.

At step I, supplier relationship practices, entered into the regression analysis. The value of adjusted R2 (=.568) indicated that the maximum amount of various in response to queries was attributable to information and communication technology practices.

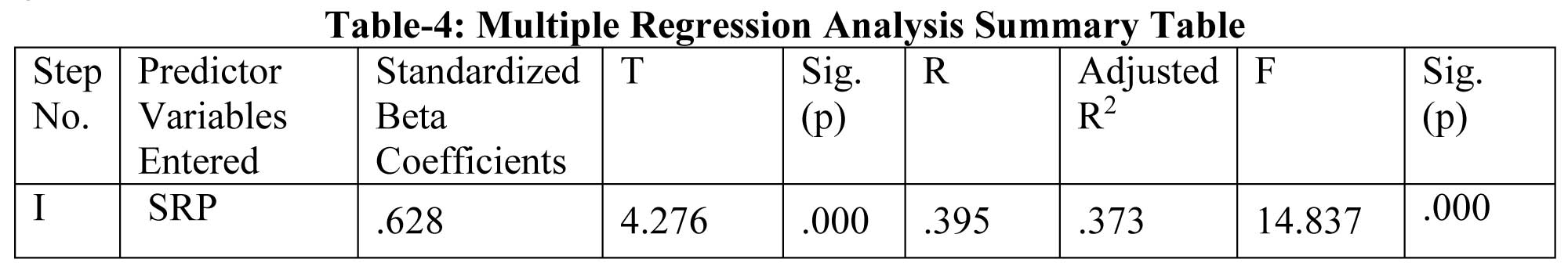

Standardized Beta coefficients, .761 (p=.000), for the one predictor variables, of multiple regression analysis indicated that one unit increase in the Supplier relationship practices was likely to significantly increase the mean value of dependent variable, backorder rate, by.761 unit.Summary of Multiple Regression Analysis of the dependent variable, “Cash to Cash Cycle” is given in Table 4.

For dependent variable ‘on cash to cash cycle’, one significant predictor variables was found i.e. supplier relationship practices (SRP), (F=14.837, p=0.000). The variable has a positive significant correlation with the dependent variable.

For dependent variable ‘on cash to cash cycle’, one significant predictor variables was found i.e. supplier relationship practices (SRP), (F=14.837, p=0.000). The variable has a positive significant correlation with the dependent variable.

At step I, supplier relationship practices, entered into the regression analysis. The value of adjusted R2 (=.373) indicated that the maximum amount of various in response to queries was attributable to supplier relationship practices.

Standardized Beta coefficients, .628 (p=.000) for the one predictor variable, of multiple regression analysis indicated that one unit increase in the supplier relationship practices was likely to significantly increase the mean value of dependent variable, cash to cash cycle, by.628 unit.

Multiple Regression Analysis

[Milk Cooperative Employee’s Opinion on Performance Metrics]

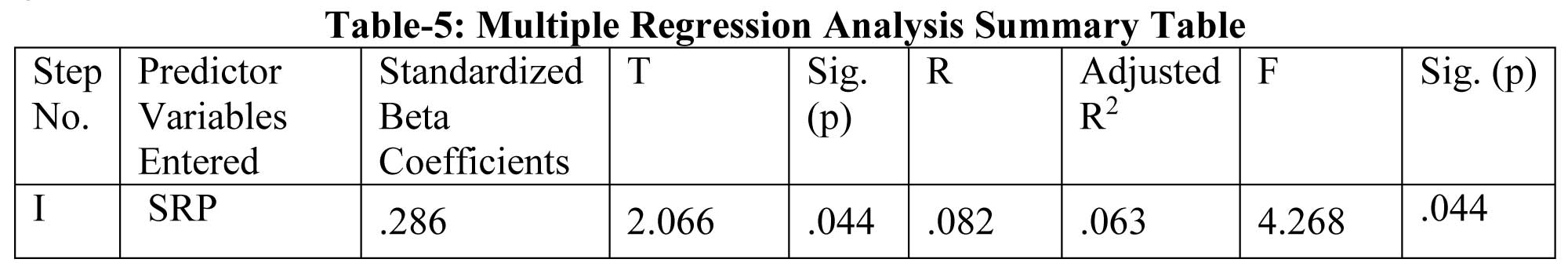

Summary of Multiple Regression Analysis of the dependent variable, “Procurement Cost” is given in Table 5.

For dependent variable ‘procurement cost’, one significant predictor variables was found i.e. supplier relationship practices (SRP) (F=4.268 p=0.044). The variables had a positive significant correlation with the dependent variable.

At step I, supplier relationship practices (SRP), entered into the regression analysis. The value of adjusted R2 (=.063) indicated that the maximum amount of various in response to queries was attributable to supplier relationship practices (SRP).

Standardized Beta coefficients, .286 (p=.044), for the one predictor variables, of multiple regression analysis indicated that one unit increase in the supplier relationship practices (SRP) was likely to significant increase the mean value of the dependent variable, procurement cost, by.286 unit.

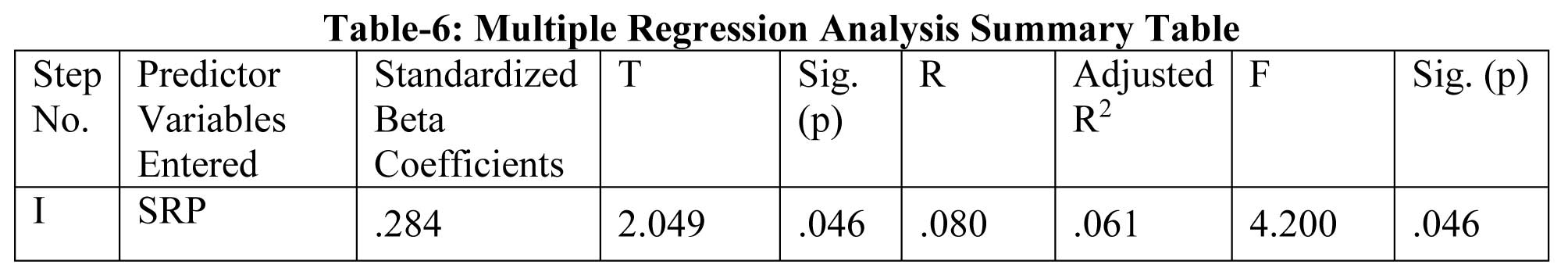

Summary of Multiple Regression Analysis of the dependent variable, “Level of Supplier Defect Free” is given in the Table6.

For dependent variable ‘level of supplier defect free’, one significant predictor variables was found i.e. supplier relationship practices (SRP) (F=4.964, p=0.031). The variable has a positive significant correlation with the dependent variable.

At step I, supplier relationship practices (SRP), entered into the regression analysis. The value of adjusted R2 (=.061) indicated that the maximum amount of various in response to queries was attributable supplier relationship practices (SRP).

Standardized Beta coefficients, .284 (p=.046), for the one predictor variable, of multiple regression analysis indicated that one unit increase in the Supplier relationship practices (SRP) was likely to significantly increase the mean value of dependent variable, sales growth, by.284 unit.

Multiple Regression Analysis

[Milk Retailer Employee’s Opinion on Performance Metrics]

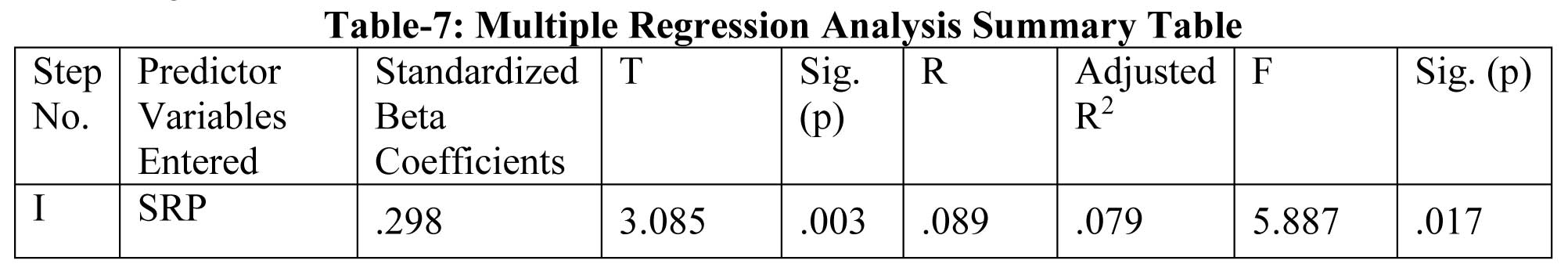

Summary of Multiple Regression Analysis of the dependent variable, “Order Fulfillment Cycle Time” is given in Table 7.

For dependent variable ‘order fulfillment cycle time’, one significant predictor variable was found i.e. supplier relationship practices (SRP) (F=5.887, p=0.017). These variables had a positive significant correlation with the dependent variable.

At step I, supplier relationship practices, entered into the regression analysis. The value of adjusted R2 (=.079) indicated that the maximum amount of various in response to queries was attributable to supplier relationship practices.

Standardized Beta coefficients, .298 (p=.003), for the one predictor variable, of multiple regression analysis indicated that one unit increase in

the supplier relationship practices was likely to significantly increase the mean value of dependent variable, order fulfillment cycle time by.298

unit.

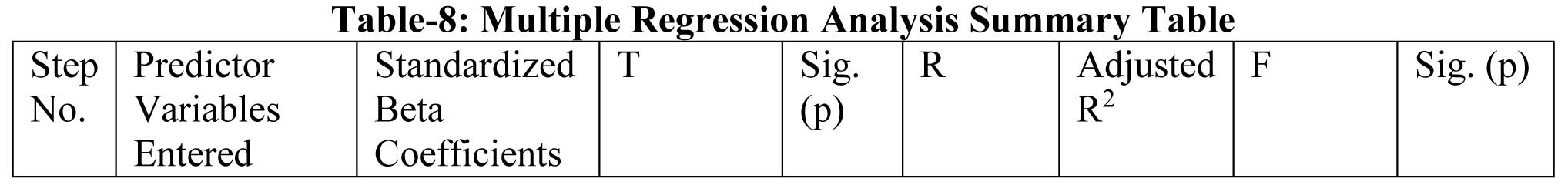

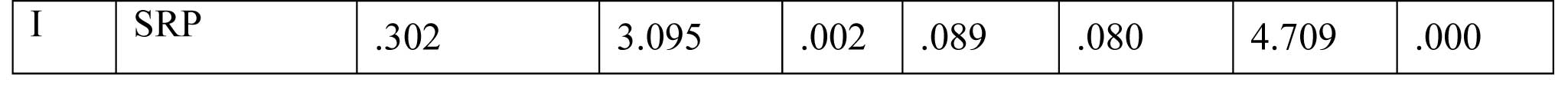

Summary of Multiple Regression Analysis of the dependent variable, “Cash to Cash Cycle” is given in Table 8.

For dependent variable ‘cash to cash cycle’, one significant predictor variables was found i.e. supplier relationship practices (SRP) (F=4.709, p=0.000). The variable has a positive significant correlation with the dependent variable.

For dependent variable ‘cash to cash cycle’, one significant predictor variables was found i.e. supplier relationship practices (SRP) (F=4.709, p=0.000). The variable has a positive significant correlation with the dependent variable.

At step I, supplier relationship practices, entered into the regression analysis. The value of adjusted R2 (=.080) indicated that the maximum amount of various in response to queries was attributable to supplier relationship practices.

Standardized Beta coefficients, .302 (p=.002), for the one predictor variables, of multiple regression analysis indicated that one unit increase in the supplier relationship practices was likely to significantly increase the mean value of dependent variable, cash to cash cycle by.302 unit.

Hypothesis Testing:

Supplier relationship practices would serve as an enabler to improve organizational performance (H1).

Multiple regression analysis was performed to check the proposed hypothesis on DP, MC, and MR. As per analysis discussed earlier, supplier relationship practices (SRP) emerged as organization performance predictor variables such as level of supplier’s defect-free deliveries, on time delivery, backorder rate, on time delivery, cash to cash cycle time in the case of the dairy plant (DP). Similarly, supplier relationship practices (SRP) linked with procurement cost and level of supplier’s defect-free deliveries performance predictor of the milk cooperative (MC). For milk retailer (MR), supplier relationship practices (SRP) is associated with order fulfillment cycle time and cash to cash cycle time.

In conclusion, the alternate hypothesis (H1) is accepted for all the dairy supply chain members i.e., DP, MC & MR.

Conclusion based on Multiple Regression Analysis on Performance Metrics [Appearing only in Dairy Plant (DP), Milk Cooperative (MC) and Milk Retailer (MR) Questionnaire]

Multiple regression analysis was performed on the dairy plant (DP), milk cooperative (MC) and milk retailer (MR) questionnaire in order to find out the impact or role of adopted SRP practices on organizational performance matrix.

From the above analysis for dairy plant, it was found out that there is various organizational performance parameter i.e. level of supplier’s defect-free deliveries”, “on time delivery”, “backorder rate” and cash to cash cycle time” which were dependent on adopted SRP practices.

Similarly, multiple regression analysis was performed on milk cooperative (MC) and milk retailer (MR) questionnaire and was found that there are various organizational performance parameter i.e. “procurement cost”, and “level of supplier’s defect-free deliveries”, for milk cooperative and “cash to cash cycle time”, for milk retailer were dependent on adopted SRP practices.

So, it can be concluded from the above-mentioned result that there is significant impact or role of adopted SRP practices on organizational performance matrix.

Recommendations based on Multiple Regression Analysis on Performance Metrics [For Dairy Plant (DP), Milk Cooperative (MC) and Milk Retailer (MR) Questionnaire]

For the dairy plant, four performance parameters were found dependent supplier relationship practices (SRP). Firstly, level of supplier’s defect-free deliveries is dependent on SRP practices. SRP entails creating closer and more collaborative relationship with key suppliers in order to uncover and realize the new value and reduce risk. Relationship quality can represent a competitive advantage for dairy supply chains and should, therefore, be improved using tools of supplier relationship management. Milk buyers can build a loyal base with their suppliers as a mean to secure uninterrupted and defect free milk-supplies. One of the major efforts which should be made is that milk buyers are encouraged to use collaborative communication with their suppliers by having frequent communication, proper feedback and adequate information sharing with their supplier which encourages problem-solving and avoids misunderstandings in their relationships. Secondly, on-time delivery is dependent on supplier relationship practices. Supplier selection processes comprise of criteria of selection, supply base optimization and commitment of buyer-supplier dyads in continuous improvement etc. Dairy companies should develop the criteria of selection and make the supplier selection process objective and transparent. The interaction between dairy companies and their suppliers will become systematized leading to a system based quick response to suppliers queries. Supplier relationship processes need to be developed and strengthened. Long-term relationships between buyer and supplier will result in greater mutual understanding and enhance people to people contact. A mutual relationship leads to courteous behavior between the persons and organizations. Relationship maintenance mechanisms such as supplier meet, handling of suppliers complaints, continuous improvement program involvement of key suppliers in product development process, risk and reward sharing, supplier involvement in planning & goal setting build the strong supplier relationship which further ensures the movement of material en time from supplier end to customer end. Thirdly, backorder and cash to cash cycle time are dependent on supplier relationship practices. Dairy companies should rely on few dependable key suppliers. They should consider quality as a preferred criterion in selecting suppliers. Dairy companies need to regularly solve the problems jointly with suppliers and follow continuous improvement programs with key suppliers. Dairy companies should actively involve key suppliers and key customers in new product development processes and also develop an efficient procurement system for finding long-term supply chain partners which will finally help in minimizing the backorder rate. Dairy companies should use electronic mode of transaction and e-procurement for minimizing cash to cash cycle time. An online payment facility reduces the cash to cash cycle time.

Similarly, for the milk cooperative, two performance parameters were found dependent supplier relationship practices (SRP). Firstly, Procurement cost is dependent on ‘supplier relationship management’ (SRM) of the milk cooperative. Milk cooperative should ensure that the activities related to minimizing procurement cost get momentum from ‘supplier relationship management’ (SRM) practices. Procurement cost is the cost involved in obtaining all goods, services, a capacity which is necessary for running, maintaining, and managing the firm’s primary and support activities at the most favorable condition. Milk cooperative should adopt good supplier relationship practices (SRP) which entails creating closer and more collaborative relationship with key suppliers in order to uncover and realize the new value and reduce risk. Relationship quality can represent a competitive advantage for dairy supply chains and should, therefore, be improved using tools of supplier relationship management. Milk buyers can build a loyal base with their suppliers as a mean to secure uninterrupted milk-supplies. One of the major efforts which should be made is that milk buyers are encouraged to use collaborative communication with their suppliers by having frequent communication, proper feedback and adequate information sharing with their supplier which encourages problem-solving and avoids misunderstandings in their relationships. Secondly, level of supplier’s defect-free deliveries is dependent on SRP practices which are defined in a dairy plant.

Likewise, for the milk retailer, one performance parameters was found dependent supplier relationship practices (SRP). Cash to cash cycle time is dependent on supplier relationship practices. Milk retailers should use electronic mode of transaction and e-procurement for minimizing cash to cash cycle time. An online payment facility reduces the cash to cash cycle time. Milk retailers need to develop a communication system for smoothening the continuous information exchange with their supply chain partners which is also required for demand & supply forecasting, production planning, inventory management and sharing knowledge of core business processes with supply chain partners.

References :

- Chandra, K., & Kumar, S (2000), Supply chain management in theory and practices: a passing fad or a fundamental change? Industrial Management and Data System, 100(3), pp.100-113.

- Chen, J., Paulraj, A., Lado (2008),An inter-organizational communication as a relational competency: antecedent and performance outcomes in collaborative buyer-supplier relationship, Journal of Operations Management, 26(1),pp. 45-64.

- Handfield, R.B. and Bechtel, C (2002),The role of trust and relationship structure in improving supply chain responsiveness, Industrial Marketing Management, 31(4), pp.36-82.

- Harland, C., Lamming, R. and Cousins, P (1999), Developing the concept of supply strategy, International Journal of Operations & Production Management, 19(7), pp.650-673.

- Harrison, A. and New, C. (2002). The role of coherent supply chain strategy and performance management in achieving competitive advantage: an international survey, Journal of the Operational Research Society, 53,pp. 263-271.

- Huo, B., Selen, W., Yeung, J.Y. and Zhao, X (2008), Understanding drivers of performance in the 3PL industry in Hong Kong. International Journal of Operations & Productions Management, 28(8), 772-800.

- Jabbour, L.S., & Jabbour, J.C (2009), Are supplier selection criteria going green? Case studies of companies in Brazil. Industrial Management and Data System, 9(4), 477-495.

- Kannan, V.R. and Tan, K.C (2005), Just in time, total quality management, and supply chain management: understanding their linkages and impact on business performance, Omega, 33, pp.153-62.

- Krause, D. and Ellram, L. (1997). Critical elements of supplier development: the buying firm perspective, European Journal of Purchasing & Supply Management, 3(1),pp. 21-31.

- Li, S., Ragu-Nathan, B., Ragu-Nathan, T. S., & Subba Rao, S. (2006) The impact of supply chain management practices on competitive advantage and organizational performance. Omega, 34(2), pp.107–124.

- Maloni, M. and Benton, W (1997) Supply chain partnerships: opportunities for operations research, European Journal of Operations Research, 101,pp. 419-29.

- Monczka, R., Callahan, T. and Nichols, E (1995), Predictors of relationships among buying and supplying firms, International Journal of Physical Distribution & Logistics Management, 25(10),pp. 45-59.

- Ou, C. S., Liu, F. C., Hung, Y. C. and Yen, D. C (2010), A structural model of supply chain management on firm performance, International Journal of Operations & Production Management, 30(5), pp.526-545.

- Ragatz, G., Handfield, R. and Scannell, T (1997), Success factors for integrating suppliers into new product success factors for integrating suppliers into new product development, Journal of Production & Innovation Management, 14(3),pp. 190-202.

- Shin, H., Collier, D.A., Wilson, D.D (2000), Supply management orientation and supplier/buyer performance. Journal of Operations Management, 18(3), pp.317–333.

- Spekman, E.R., Kamauff, W.J. and Muhr, N. (1998). An empirical investigation into supply chain management, International Journal of Physical Distribution & Logistics Management, 28(8),pp. 630-650.

- Spekman, E.R., Kamauff, W.J. and Muhr, N(1998), An empirical investigation into supply chain management, International Journal of Physical Distribution & Logistics Management, 28(8), pp.630-650.

- Stanley, L.L., Wisner, J.D (2001), Service quality along the supply chain: implications for purchasing. Journal of Operations Management, 19(3),pp. 287–306.

- Stuart, I. and McCutcheon, M. (2000) The manager’s guide to supply chain management, Business Horizons, 43(2), pp.35-44.

- Stuart, I. and McCutcheon, M. (2000). The manager’s guide to supply chain management, Business Horizons, 43(2),pp.35-44.

- Walter, A., Muller, T., Helfert, G. and Ritter, T. (2003). Functions of industrial supplier relationships and their impact on relationship quality, Industrial Marketing Management, 32,pp. 159-69

- Wisner, J.D. & Fawcett, S.E. (1991), Linking firm strategy to operating decision through performance measurement. Production and Inventory Management Journal, 32,pp. 5-11.

- Wynstra, T. and Pierick, E. (2000), Managing supplier involvement in new product development: a portfolio approach, European Journal of Purchasing & Supply Management, 6, pp.49-57.