Subscribe now to get notified about IU Jharkhand journal updates!

A Study On Employee's Perception Of Workplace Safety In Auxiliary Industries

Abstract :

This study examained the Employee attitudes on the implementation of safety and health measuresin auxiliary industries were investigated in this study. Training, work environment, mechanical, ergonomics, personal protection equipment (PPE), electrical, and noise were among the seven (7) factors that were collected utilising a set of questionnaires. The replies were graded on a five-point Likert scale ranging from "strongly disagree" to "strongly agree." A total of 40 people responded to the survey, which was conducted at a small auxiliary industry and included all employees. The mean score and standard deviation were calculated using descriptive statistics to analyse the data. The perception of mechanical components had the lowest mean score; additionally, 51.7 percent of the employees had negative perceptions (combination of 'disagree' and' strongly disagree')

Keywords :

Employees' perception, occupational safety, auxiliary industriesIntroduction

All industrial facilities need ancillary processes to support the production process. These include power generation and electricity. Organizations are at risk whenever they open their doors to businesses, whatever their size. At any time, an employee may be hurt, a customer may have an accident or a consumer may be hurt using the organization's product. In order to establish a safe workplace in any industry, an effective and adequate safety and health system is considered the most important. Today, issues related to the organizational and management impact on safety performance, particularly the function of health and safety. The major issue that normally relates to ancillary industries and management is the majority of organizations lack financial resources and at the same time they do not have management skill to manage the organization. The Auxiliary industries are facing with the problem of high workplace accident rate This could be a reflection of how they manage the OSH management system in their companies. The government has undertaken steps to improve OSH that are aimed at everyone enterprises, however the participation from Auxiliary industries were very poor (Lee Lam Thye, 2010). Lee Lam Thye (2010) also stated that in Auxiliary industries, safety and health are often viewed as counterproductive to the operation and never treated as a crucial part of the overall management of the organization. By measuring the employee's level of satisfactions on OSH implementation, it will assist Auxiliary industries in initiating improvement in the specific target area. This will definitely allow the usage of limited resources and cultivate the culture of making small improvement on regular basis.

The absence of safety objectives, explicit safety policies, and systematic preventative effort reflects a lack of commitment to safety management. This situation will greatly influence the employees' perception towards OSH management in the organization. According to Fernandez-Muniz et al. (2009), policies, strategies and procedures should be included and be fully integrated into organization to establish a good safety management system . The dominant top priority for the employees is productivity whereas OSH management does not seem to be part of organization. Nevertheless, today, safety management is no longer treated as secondary in the business context rather it is treated as a culture. It is critical for employers to realize the positive relationship between OSH and competitiveness in order to motivate them to establish a safe and healthy work environment. Vredenburgh (2002) stated that organizations can derive a financial benefit in reduced lost time and workers compensation expenses. This is resulted by proactive measures taken by organizations to protect their employees. Previous study conducted by Fernandez-Muniz et al. (2009) has shown the positive relationship between safety management system and competitiveness performance. The more developed the system is: (1) the higher the quality of the firm's product and services,

(2) The higher the productivity,

(3) the higher the customer satisfaction and the better the firm's reputation and image, and (4) the higher the firm's degree of innovation, due to the technological and organizational innovations derived from the improvements in safety.

The study also concluded that safety management system reduces both personal harm and material damage. Thus, the company will be able to retain workers with specific knowledge who are difficult to replace since the system has increase the employees' motivation and as the result it makes them less likely to leave the company.

THE LITERATURE REVIEW

Hanvold T N et.al (2016) Young workers in the Nordic countries are mostly employed in wholesale/retail, accommodation/food/beverage services, health services, and construction. National statistics from each of the five Nordic countries also reveal that young workers have almost twice the risk of experiencing an accident at work compared to their older colleagues. They also face potentially harmful exposures and hazardous work to a greater degree than older workers.

Hasle P et.al (2013) When the five Nordic countries are referred to in a work life context, they are often presented as the "Nordic model", sharing similarities regarding the labor market, with collective bargaining and solidarity-based welfare systems. There are also sociocultural similarities between the five Nordic countries, indicating that young workers face many of the same conditions and challenges. This enables the comparison of literature and facilitates the identification of vulnerable groups within the young working force that may need special attention.

Maria Cristina Arcuri et.al (2016) Safety at work is a challenging issue for firms and governments worldwide. This paper presents a comprehensive literature review on occupational accidents. We analyze causes of injury and risk factors, economic and social consequences, Occupational Health and Safety Management System areas of priority and effectiveness of interventions. We highlight the key role of workers and of prevention programs. Accident prevention is a means of reducing negative effects of accidents and increasing productivity. Furthermore, prevention can raise creditworthiness and lower insurance premiums.

ILO, 2014 Occupational health and safety (OHS) is a widely debated and important issue. Although considerable progress has been made in protecting workers from occupational injury, too many employees die or are injured every year. Worldwide, every year, there are about 2 million deaths caused by accidents at work or occupational diseases.

Accident and injury can be defined as adverse events in a production process. Production involves different kinds of energy interactions in a controlled environment. But sometimes control is lost, and an uncontrolled energy transfer occurs, leading to an accident or injury incident. Some studies (Langley, 1988) use the terms accident and injury synonymously. However, not every accident leads to injury, but every injury derives from an incident (Khanzode et al., 2012).

Specifically, injury is a (suspected) bodily lesion resulting from acute overexposure to energy interacting with the body in amounts or rates that exceed the threshold of physiological tolerance (ICECI, 2004). In general, risk is the "considered expected loss or damage associated with the occurrence of a possible undesired event" (Nieuwhof, 1985).

Occupational injury risk is the likelihood of getting injured while executing a job. All enterprises are exposed to this kind of risk and identification of hazards (for example, radiation, rapid pressure changes, mechanical shocks) should be a key activity. Identification of hazards is the first step in assessing risk of injury in a work system.

Willquist and Torner (2003) describe three main approaches of hazard identification: (1) biased reactive approach, (2) biased proactive approach and (3) unbiased proactive approach. The first approach is based on the analysis of information after an accident. The second approach is based on identifying hazards using historical data from the system. The third approach is based on the analysis of the potential hazardous elements and potential targets (persons or equipment); in other words, analysis before the accident occurs.

However, hazard identification requires knowledge of the work system because hazards often are specific to the workplace (Maiti, 2005).

RESEARCH METHODOLOGY

Sampling

The survey was conducted at an auxiliary industry where the main office and the factory is located in Mylapore, Chennai. The company has established since 1975 and they started with one (1) product in the beginning. Currently, they are producing more than 30 products in the market. The products produced are mainly Fabrics, clothes and dyes. The company is categorized as a small sized enterprise as referred to the new definition endorsed by 14th National SME Development Council meeting in July 2013. The numbers of respondents involved are 40 respondents which include all the employees from four (4) departments: mixer, extruder, dryer and packaging. 22 of the respondents are male, while 18 of the respondents are female. The age range is from 18 years old until 34 years old and above. Work experience is also taken into consideration in this study.

Instrument for Data Collection

A survey method was used. Part A and Part B of the survey questions were divided into two (2) sections. Part A of the survey consisted of demographic questions about respondents' age, gender, department, and years of experience, as indicated in Table 1. Part B included seven (7) variables: training, work environment, mechanical, ergonomics, personal protective equipment, electrical, and noise. The factors were chosen depending on the organization's work environment. The purpose of the survey was to determine employee satisfaction with OSH procedures adopted in the organisation, as well as employee perceptions of their risk exposure. The survey instrument is summarised in Table 1. These items were graded on a five-point Likert scale (5: Strongly Agree, 1: Strongly Disagree).

ANALYSIS AND INTERPRETATION

Demographic Profile

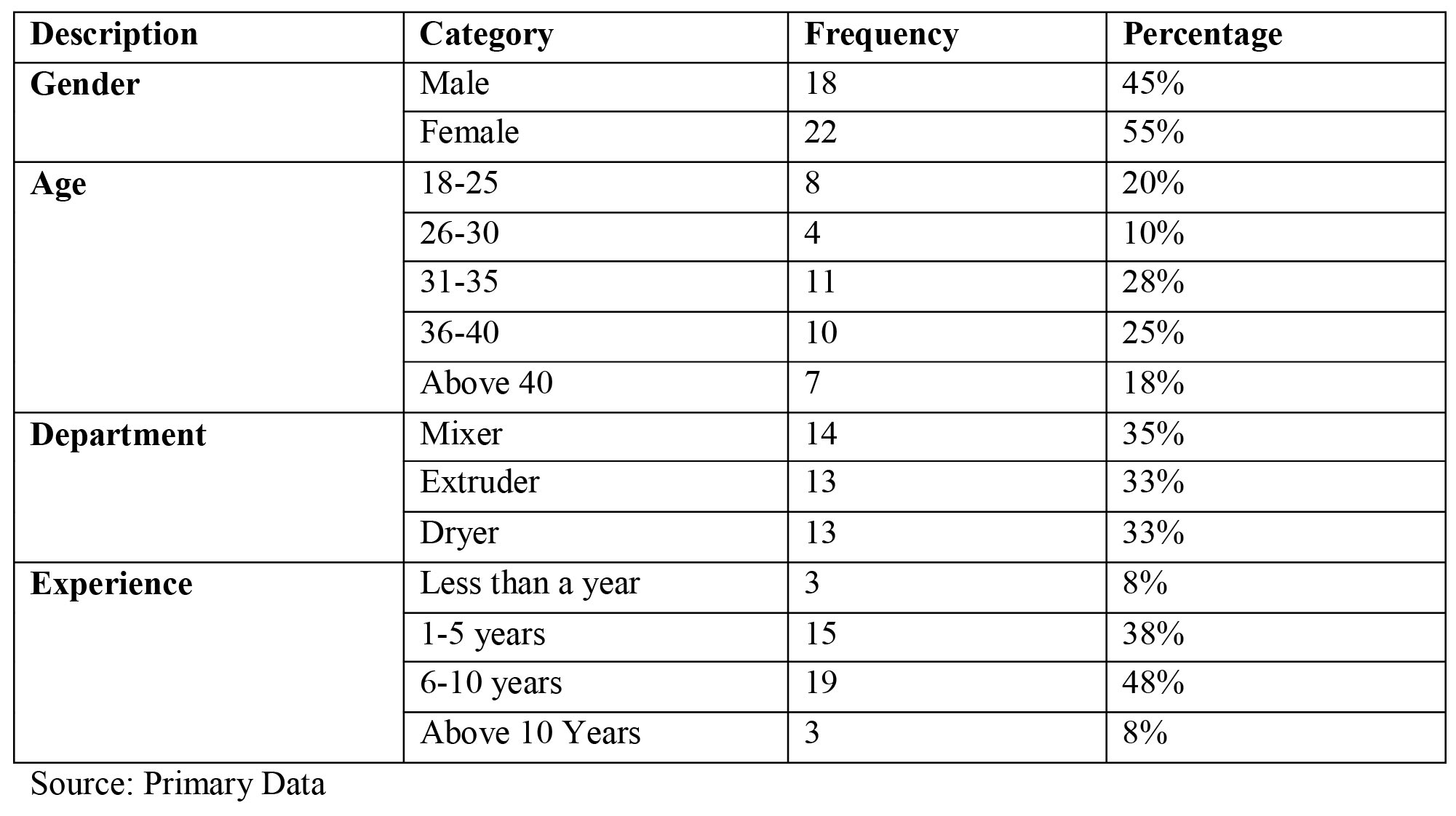

The profile of the study sample acquired in this investigation is shown in the table below. Female employees make about 55% of the entire workforce. The majority of those who responded were between the ages of 31 and 40. The total number of respondents from that group was 21, accounting for more than half of the total number of respondents. Seven (7) of the respondents were over the age of 41. The oldest respondent was 52 years old. Employees who are older are more likely to be affected by negative health impacts that result from their exposure to chemical, physical, or biological dangers in the workplace; for example, the risk of hearing loss connected with exposure to excessive loudness (Goetsch, 2005). Younger employees, on the other hand, are regularly hurt.Table 1: Demographic Profile

As responded in the questionnaire, 35% of the respondents involved in mixer department, 32.5% in extruder department and another 32.5% dryer department. However, in packaging department it involves six (6) to seven (7) workers in every shift. The employees from other departments are assigned to work in packaging department depending on their work schedule. 47.5% of the respondents have six (6) to 10 years working experience in the company and 37.5% of the respondents have one (1) to five (5) years of working experience. Only three (3) respondents have experience less than one (1) year. The duration of working experience has always been the indicator for competency and work performance quality level. Yet, research conducted by Shaikhah, Sarmad & Wafi, 2009 has proven that training and education play major role in developing the level of competency in employees. It is vital for the employers to provide sufficient training and education sessions to enhance employees' capability in completing their tasks particularly for newly hired employees.

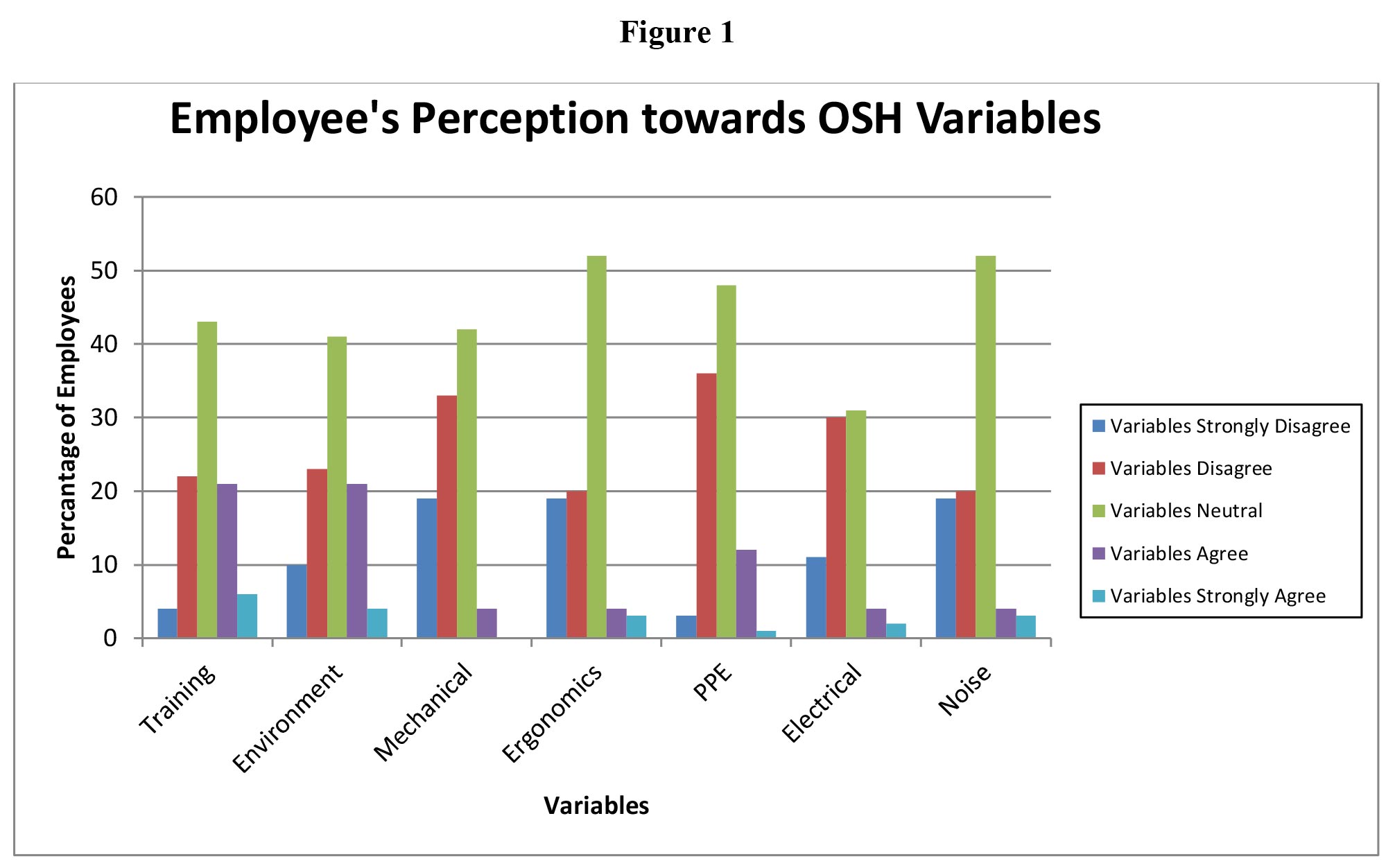

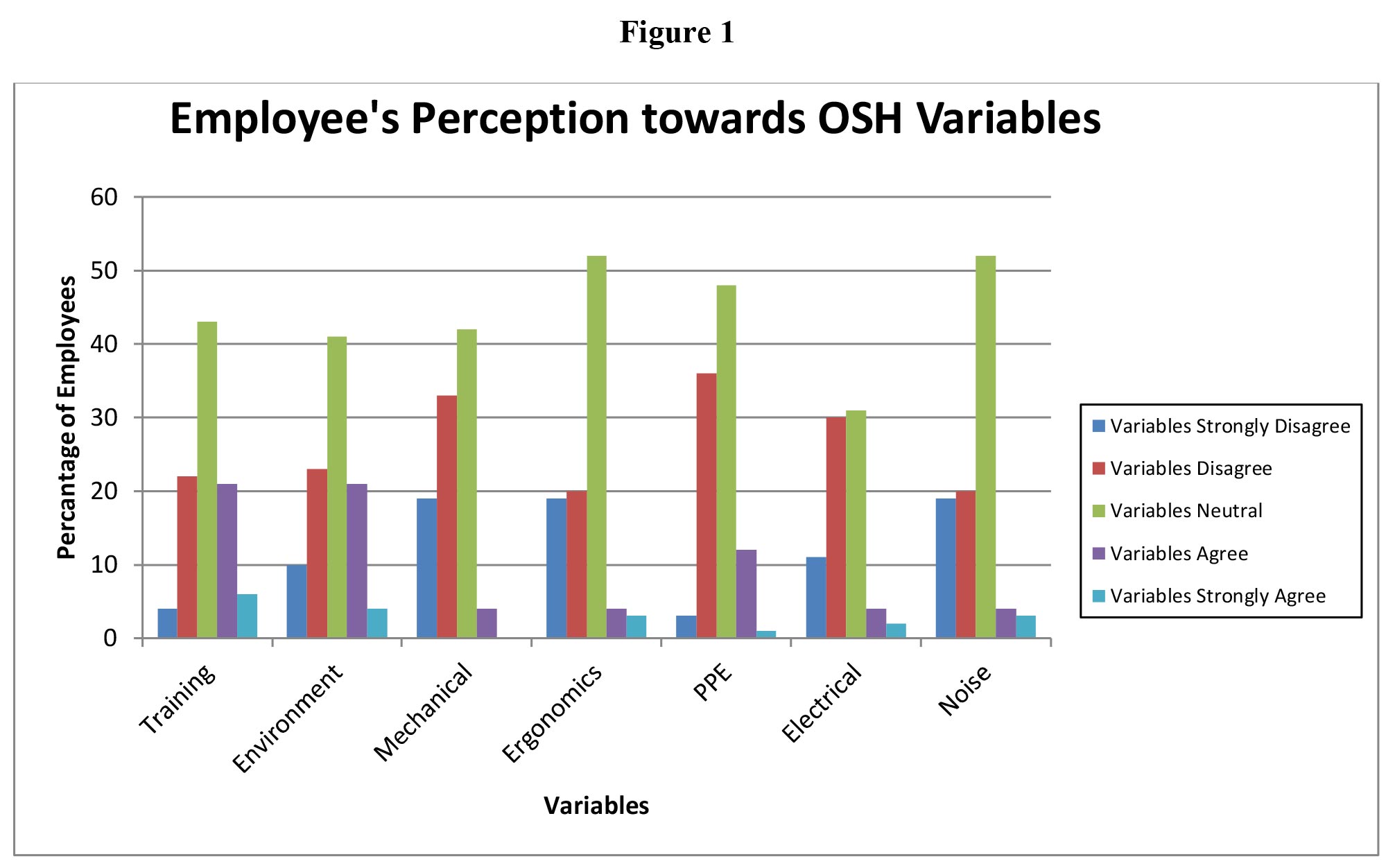

Descriptive statistics were used to measure the variables related to OSH in order to study the perception of respondents towards the implementation of OSH in their workplace. Employees' perception was measured using seven (7) variables as shown in Table 2. Table 2 shows the result of reliability test done. The result was based on Cronbach's alpha value. In conclusion, the questions were reliable since the values of alpha were from 0.764 to 0.912. The overall Cronbach's Alpha value for the 23 items was 0.814. The mean score and standard deviation also shown in Table 2. As indicated by the survey results, the mean score for all the variables were below 3.00 (average) except for training (µ=3.01). Among the elements, mechanical aspect was perceived as rather low with mean score of 2.35. It is followed by ergonomics (µ=2.56) and PPE and noise (µ=2.71). The results also indicated that PPE scored the lowest standard deviation value which shown the respondents' response tend to be very close to the mean score for that particular variable. The overall results display that the general perceptions of employees with regard to the OSH implementation were low. The details of the survey results are summarized in Figure 1.

As referred to Figure 1, the combined percentages for disagree and strongly disagree for all the variables ranging from 27.5% to 51.7%. These results show that most of the respondents have negative perceptions towards the variables included in the questionnaire. The negative perceptions are most probably contributed by employees' dissatisfaction towards OSH management and overall working environment in their workplace. The dissatisfaction can be clearly seen for mechanical variable which the items generally related to tools and equipment, and the platforms being used to complete the tasks. Poor maintenance of tools and equipment used by employees will increase the probability of accident.

The mean score for ergonomics also displayed low mean score (2.56). The items stated in ergonomics were related to repetitive tasks and back pains. Repetitive tasks will cause musculoskeletal disorders (MSDs) which are injuries of the muscles, nerves, tendons, ligaments, joints, cartilage, or spinal discs. MSDs are not typically the result of any instantaneous or acute event (such as a slip, trip, or fall) but reflect a more gradual or chronic development. MSDs may cause a great deal of pain and suffering among afflicted workers, therefore the productivity and the quality of products and services will be decreased.

Workers experiencing aches and pains on the job may not be able to do quality work. The OSH variables involved can be classified as the causes for psychosocial hazards. Psychosocial hazards are characterized by factors such as job content, workload and workplace, work schedule, control, environment and equipment, organizational culture and function, interpersonal relationships at work, role in origination, career development and home-work interface (Cox, 1993). Higher levels of unsafe work behaviour have been associated with higher psychological job demands (Hofmann & Stetzer, 1996). One of the most popular psychosocial causes is stress. In an organization, physical hazards and working environment can be a constant source of stress for the employees (Susmita & Akash, 2012).

Stress is a pathological, and therefore generally undesirable, human reaction to psychological, social, occupational, or environmental stimuli (Goetch, 2005). Some of the conditions that can trigger stress are for example; extreme hot temperatures, high intensity sounds, and poor or extreme light. However, the study conducted by Susmita & Akash, 2012 also highlighted the fact that every industry has its own stressors and hazards and it is difficult to particularly indicate which industry has higher stress levels attached to its job nature.

CONCLUSION

Employees who have participated in safety training can recognize hazards and dangerous actions and understand their consequences. Employees trained to identify hazards associated with their workplace will have a better perception of the hazards. This will increase their compliance to warning and instructions (Vredenburgh and Cohen, 1995). Vredenburgh (2002) also indicated on the importance of systematic, comprehensive safety and health training program for new employees. As well, new employees may be offered a mentor or job shadowing system to help them adjust to safety, health and quality systems. In auxiliary industries, new employees are usually getting 'informal' training by senior employees, and sometimes they will be asked to perform their job by following others.

The purpose of the study is to examine how employees perceive the implementation of OHS management practices in the workplace. The results have shown that the employees have negative perceptions towards the variables in the questionnaire. This indicates a lack of commitment by management to the implementation of OH&S practices. Senior management needs to do more to improve OHS management and practices to build positive perceptions among employees Positive perceptions will help staff continually improve their safety performance. It is recommended that the study be conducted in other small organizations to examine the relationship between employee perceptions.

REFERENCES

- Rhaffor, Kauthar & Saparuddin, , & Maidin, ,. (2014). Employees' Perception towards Safety and Health Practices in a Small-Sized Organization.

- Guy Ryder, General Secretary of the International Labour Organization (ILO), reported this dramatic statistic at the 20th World Congress on Health and Safety at Work, Frankfurt, 24 - 27 August 2014.

- ICECI. International Classification of External Causes of Injuries. ICECI Coordination and Maintenance Group, World Health Organization, 2004.

- Nieuwhof G. Risk: a probabilistic concept. Reliability Engineering 1985; 10: 183- 188.

- Willquist P, Torner M. Identifying and analysing hazards in manufacturing industry- a review of selected methods and development of a framework for method applicability. International Journal of Industrial Ergonomics 2003; 32: 165- 180

- Maiti J. Risk assessment and safety evaluation of mining system. Journal of Institution of Engineers (India) - Mining 2005; 85: 33-41.

- Maria Cristina Arcuri, Gino Gandolfi and Riccardo Melloni. Key aspect of safety at work: A comprehensive literature review. EPH - International Journal of Science and Engineering - ISSN: 2454 - 2016.