Subscribe now to get notified about IU Jharkhand journal updates!

HR analytics and Industry 5.0 in the Performance Management System of the coal mining industry

Abstract :

To keep at par with the ever-changing and cut-throat competitive world, the advent of Industry 5.0 has been a blessing for the field of Human Resources. For making the HR processes quicker and smarter, the arriving of Industry 5.0 and HR analytics have made it possible to make for the HR to measure the performance of the employees easier. This paper talks about the new software’s like SAP, systems like PRIDE, CR, VIDHIK, EIS and installation of new age AI-enabled machines like in-pit crushing and conveying, photogrammetry and remote sensing, GIS, OITDS, government schemes like UTTAM app, Shakti, Khan Prahari, CMSMS have made the mining sector work more robust, smoother, moving towards sustainable development, reducing human error and incidents in mines. This paper includes about the exciting Balance Scorecard based performance management system, how it has eased the performance measuring of employees, its dynamic nature and user-friendly approach. To understand with a real-life example, a case study showing how implementation of disruptive technology can enhance the performance of mines, is provided. With the increasing economic crises of the fossil fuels, there is need of more industrial, economical, strategic reforms in the mining industry. Keywords- HR analytics, Performance Management System, Industry 5.0, coal mining sector

Introduction

1. Introduction

Industry 5.0 "offers a vision of industry that strives beyond efficiency and productivity as the main goals and reaffirms the role and contribution of industry to society," according to the European Union. and "It respects the planet's production limits while putting the welfare of the worker at the centre of the production process and using new technology to bring prosperity beyond jobs and growth." By "particularly putting research and innovation at the service of the transition to a sustainable, human-centric, and resilient European industry," it enhances the industry 4.0 strategy. Industry 4.0 is still ongoing in its speed but the concept of more automation, sustainability and smart work has emerged the concept of Industry 5.0. Mainly, the focus of Industry 5.0 is societal value than economic and more wellbeing from welfare. This concept has gained even more importance after the Covid-19 pandemic, as that pandemic has made us see the worse but have also made us realise the need of more autonomous machines yet human-centric, sustainable, and resilient approach. This concept is also making us move towards the UNDP SDGs (Sustainable Development Goals) or Global Goals were adopted by the UN in 2015 to bring social, economic, and environmental sustainability, climate change being a major challenge and all the 17 goals being inter-related to one another. Mining sector is the oldest and important sector for the boosting up of many industries phase. The new developments like AI based machines, sensors, operations have made the mining sector move towards the accomplishing the goals of Industry 5.0. it has made the mining sector Human resources is one of the oldest yet strongest part of any organisation also needed some improvements in flow of changing industrial dimensions. With the coming up of digitalisation in Industry 4.0, the big data and analysis came into picture thus the introduction of HR analytics. HR analytics, in simpler terms, is the analysis of the employee’s data to predict and learn the future and current scenario of the organisation respectively. The parameters like performance, satisfaction, workforce, turnover, retention etc that have been qualitative in one time has become a quantitative parameter, by analysing which any organisation can never fall apart.

2. Literature review

The data from Ministry of Coal tells us that it has been able to increase the All India coal production to 716.08 million tonnes in 2020–21 through a consistent investment programme and a higher emphasis on the deployment of current technologies (Provisional). The production of coal over all of India in 2021–22 increased by a positive 8.67% to 778.19 MT (Provisional). The largest supplier of coal to the south is Singareni Collieries Company Limited (SCCL). In contrast to the 64.044 million tonnes produced over the same period previous year, the company produced 50.580 million tonnes of coal during 2020–21. The production of coal by SCCL in 2021–22 increased by a positive 28.55% to 65.022 MT(Provisional). Other companies including TISCO, IISCO, DVC, and others also manufacture small amounts of coal. In 2020–21, Coal India Limited (CIL) and its subsidiaries produced 596.221 million tonnes, a decrease of 0.98% from the 602.129 million tonnes produced in 2019–20. The amount of coal produced by CIL in 2021–22 was 622.634 MT(Provisional), representing a rise of 4.43%. Coal being the most important fossil fuel for power generation India. In their study, Gattikunda and Jawahar, concluded that we isolated the emissions from the coal- fired power plants and estimated a premature mortality rate of 80,000 to 115,000 due to their contribution to the ambient PM2.5 concentrations. Te pollution standards exist only for ambient air quality and not for individual power plants. There is a need for tighter emission standards, efficiency improvement of existing older power plants, EIA (Environmental Impact Assessment) procedures need to be revised, depending on the need and urge for the newer and robust technology for reducing pollution from the mines.

The paper from Choi, Panniruky and Masibau titled “The impact of HRM practices on employees’ turnover intention”, they took training, compensation, and benefit. Performance management, career development and employee relation as their independent variable to the current HR practices which depends on the staff turnover intention as dependent variable. In their research , they found out that all the independent variables affect the turnover intention. A good performance appraisal system has made employees stay longer with the organisation. Compensation, being the foremost important factor, along with that the employees look for another extra

benefits like flexi-time, shorter working hours, even providing child care services etc have their say in holding back of employees (Jill, 2005).

To prove the relation between work engagement, intrinsic motivation and job satisfaction among coal mining employees, Sartono and Ardhani conducted an quantitative study employing cross-sectional survey by self-reported questionnaire of the 156 employees of South Borneo, using stratified random sampling. The results of that experiment were that an individual who feels less pressure/tension will have a higher level of work engagement, along with that there is a direct relation between perceived competence and intrinsic motivation. d. Having knowledge of the business’s internal, environmental human resources issues, allows the human resources managers of the company to deal amicably with any issues affecting the function. Having a working environment which takes into account social structures that facilitate informal activities among employees is crucial for improved employee performance. Through these informal structures, a lot of employee-related matters can be resolved since it opens up a space for communication among employees. Considering that lack of social activities (informal activities) have been a worrying issue to the majority of employees in the company, this could explain why employees in the company are averagely intrinsically motivated and engaged in their company. Understanding work engagement within the coal mining industry in South Borneo can go a long way in addressing the possible challenge of unhealthy employer employee relations resulting from inadequate employee motivation and satisfaction, which contribute to employees’ not fully applying themselves to work. This ultimately leads to organisational inefficiency and ineffectiveness, a situation which management does not hope for.

On the other hand, Sánchez and Hartlieb researched on the innovation in the mining industry and concluded that innovation is the tool to improve the efficiency of its processes, to reduce costs but also to meet the increasing social and environmental concerns. Technological advances usually have an impact on the output, allowing larger production rates while maintaining a similar workforce, or directly reducing the needed personnel by the automation of processes. Latest technologies like hydrometallurgical production method SX-EW , underground coal mining along with draglines and bucket wheel excavators in surface coal mining, in smelting processes, the development of flash, bottom blowing furnaces. Addressing safety and environmental concerns, focus has been on the on removing the employees from critical activities through automated or semi-automated machines. Innovative technologies are causing operational changes throughout the value chain and are not often used only for one activity. Intelligent operation centres, for instance, are being used for both extraction and processing activities. Similarly, digital twinning, augmented reality, and virtual reality are tools that will improve mining project design and construction as well as extraction and processing processes. Given below is the figure showing digital transformation in the different stages of the mining value chain.

Fig.1. Digital technologies in the different stages of the mining value chain.

These trends are complementary to the technologies 4.0 and provide a glimpse into the potential future directions that mining may take. They are motivated by concerns about safety and the environment, cost reduction, improving efficiency and productivity in the operation, or a combination of these factors like electromobility, invisible zero-waste mining, continuous mining.

In the mining sector, Balance Scorecard (BSC) is mostly used for the evaluation of the performance of the employees. Based on that Jou and his team has made conclusion, taking high-tech related industries in Taiwan that , BSC provides a tool for systematic measurement and management so that each internal department and strategies of the organization can be integrated closely for the focused effect. The ultimate BSC does not intend to measure performance merely; on the contrary, it motivates each department to participate in changes through reformations and offers systematic management methods for complete implementation. Perspectives of management performance are evaluated and compared by the balanced scorecard in this research. The management can measure the performance level and compare the performance indices and matrixes of themselves and the benchmarking companies according to the areas formed by the coordinates of satisfaction and importance and the target line in the performance matrixes.

Nimbalkar, in his research about the coal miners workers and motivation, concluded that job satisfaction and commitment as indicators of motivation can predict very low satisfaction. In his work in WCL (Western Coalfield Limited), he says that the hierarchy of needs according to workers were Self actualisation followed by safety and social security, depicting their low motivation level, financial motivation being the major motivating factor, human relations among themselves also proves to be a important factor.

Jelena and Ivan Bozovic, in their study of Ibarski Rudnici, Serbia, concluded that the manager should have material stimulus along with the immaterial stimulus. Employees can be motivated, praised, promoted, can gain greater responsibilities or advancement apart from the salary. In order to achieve the full effects of labor motivation in a mine company, there is a need for a combination of desirable traits of mine management with employees. Regular practice in mining companies should be measuring employee satisfaction and monitoring their needs and preferences. In order for a company to operate successfully, mining managementneeds to understand the needs and requirements of its employees, as well as to find an optimal mix of material and immaterial incentives for its employees

3. Case Study

The intensive development of mining in the area of today’s Serbia is practically practiced after the Second World War, when a large number of mines were opened under state ownership. Due to the social and economic significance and specificity of the ambient business conditions, mining has been trying to regulate its operations by the rules of operation since ancient times. The Mining Code, Mining Law or Miners’ Law enacted by Despot Stefan Lazarevic on 29 January 1412, formulated earlier in 1390 (Radojcic, 1962). An evolutionary return to the past points to the following features in mining: The orderliness, the definition of work rules, the determination of competencies, rights and obligations, normative conditionality, narrowly specialized knowledge and expertise, standardization and the like (Radosavljevic, 2016). Serbia currently has about 250 exploitation fields in which mining activities take place. Also, there are about 100 research fields, where some of the world’s largest mining companies are present. Foreign mining companies invest between $ 10 million and $ 100 million annually on geological research in Serbia. The Ibar Valley has long been recognized as a valley of mining. In written sources there are traces of mining and mining settlements in the 3rd century BC. Located between the two mountains, Kopaonik and Golija, on the road from the Apennine peninsula and the Dubrovnik region towards the Middle and the Far East. On the basis of written tracks, first mining in this region started with the exploitation of copper, then silver, gold, coal, and in recent history, mines of lead, zinc, asbestos, magnesite as well as construction and technical stone. In the village of Baljevac there is the headquarters of the Ibar coal mines, which includes the Pobrdje deposit. The first Ibar mine in the Raska municipality was opened in 1924, and it was founded by the company Savic and worked until the Second World War. During the war, he was taken over by the state and worked in disruptions. After the war, he continued to work as a state-owned company until 1992, when Elektroprivreda took over the mine and owned it until 2003. After that, all the mines were united into a public enterprise for underground coal mining (JP PEU) “Resavica.” Organizational units of the mine with 459 employees are: Jarando (2 managers and 159 employees), “Usce” (where the pit is Tadenje and the surface mine Progorelica, (5 managers and 154 workers), “Separation and Cableway” (3 managers and 112 employees) and “Professional Services” (6 managers and 34 employees). To ensure safety and safety at work, the mine applies the following standards: ISO 9000 quality management system, (QMS) 14001 environmental management system (EMS), 18001 occupational health and safety management systems (OHSAS), integrated management system: QMS (ISO 9001, EMS - 14001) and OMS (OHSAS 18001). The last few decades have seen a significant decline in mining production. The reasons for this are multiple: Outdated and incomplete legal solutions in the field of mining and geological research, inherited problems from the previous period related to the way of organization, legal status of mining companies and non-market manner of their business. Due to a certain inertia of management and expectations of problem solving by the state, lack of state, clumsy privatization in the conditions of sudden price jump, most of the mines and mining plants did not react in a timely manner to provide themselves with the benefit of improving the future.

4. Methodology

Data collected from primary and secondary sources through questionnaire and journals and articles respectively. For analysing the data, the survey has been conducted in the

S.E.C.L. Bhatgaon coal mines area. Around 100 employees working at executive and non-executive level has been examined on random basis. The variables taken to study were exciting performance management system present in the organisation, satisfaction among employees from that system, their needs (Maslow’s need of hierarchy principle was used), their level of job satisfaction (using Litcher scale of 5 levels).

The main focus of this research is to see the impact of the advancement in technology in the performance management system of the employees. For that we have taken the independent variables like easing up of process after coming of technology, satisfaction with the existing PMS of the employees according to their group, advancements in technology, their needs satisfied by their job and the dependent variable like job satisfaction.

5. Results

We have used SPSS software for the analysis of our data. We have used linear regression analysis with 95% confidence level, model fit, R-squared change, descriptive. The hypothesis we consider are as follows-

Null hypothesis: Job satisfaction has no relation with the easing up of work after coming up of technology, employees’ satisfaction with the existing PMS, needs satisfied from the job and grade of employees.

Alternate hypothesis: Job satisfaction is dependent on the easing up of work after coming of the technology, employees’ satisfaction with the existing PMS, needs satisfied from the job and grade of employees.

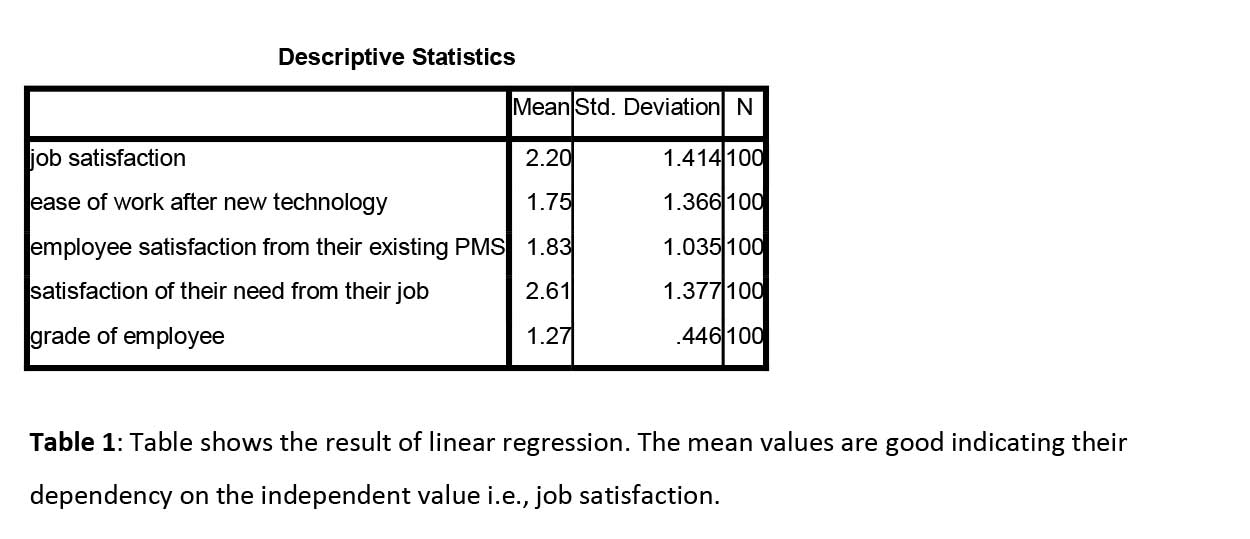

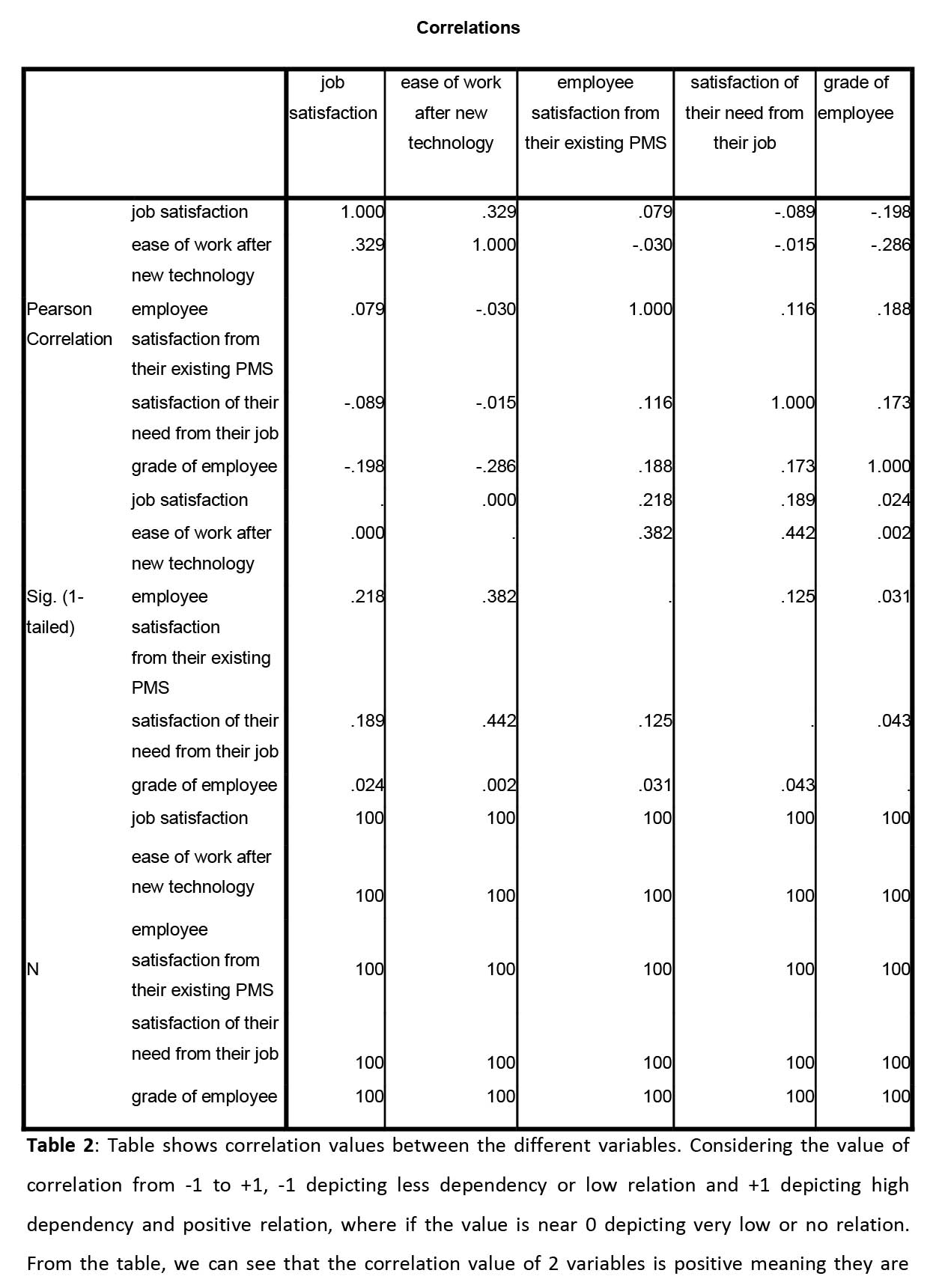

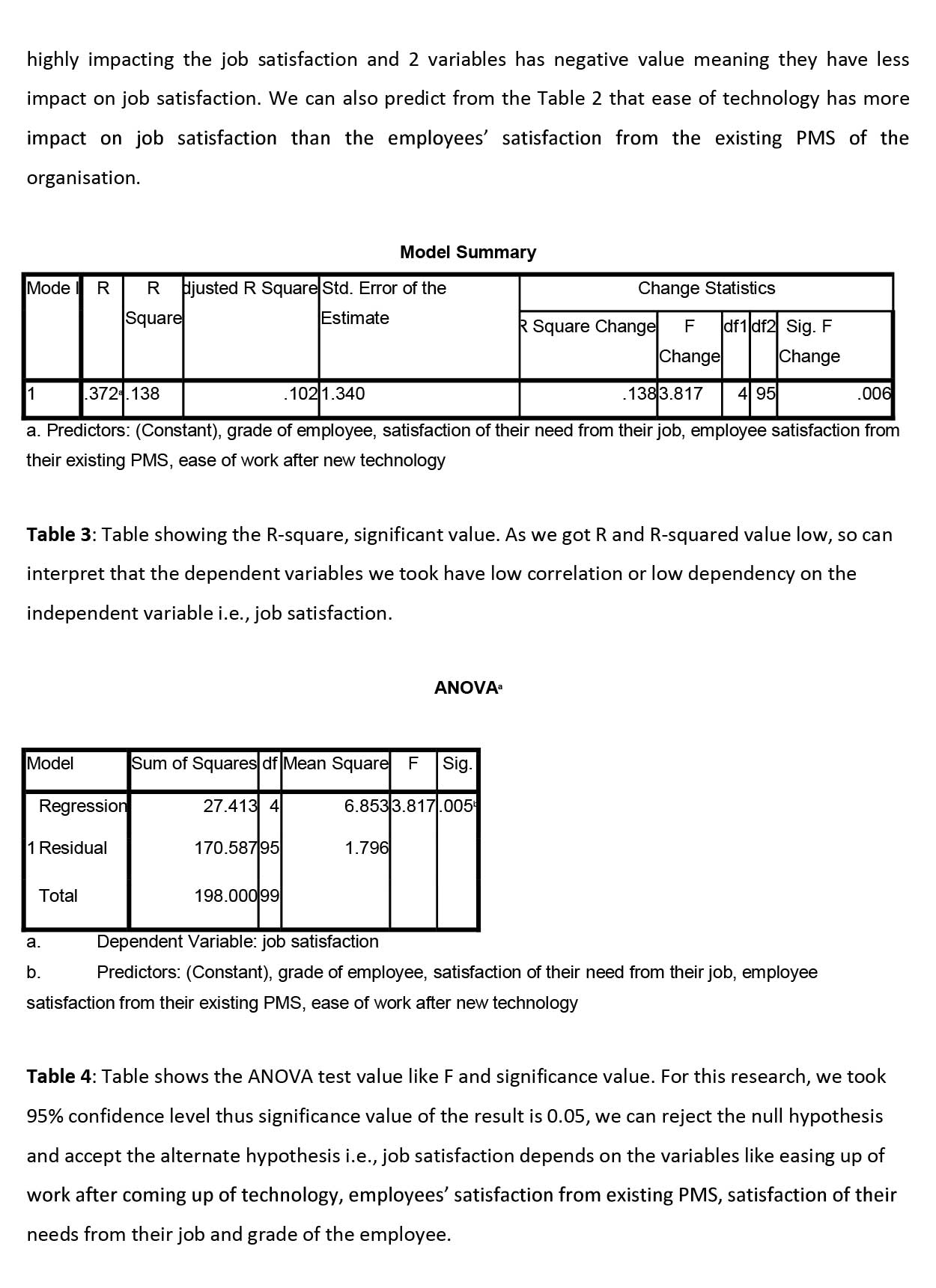

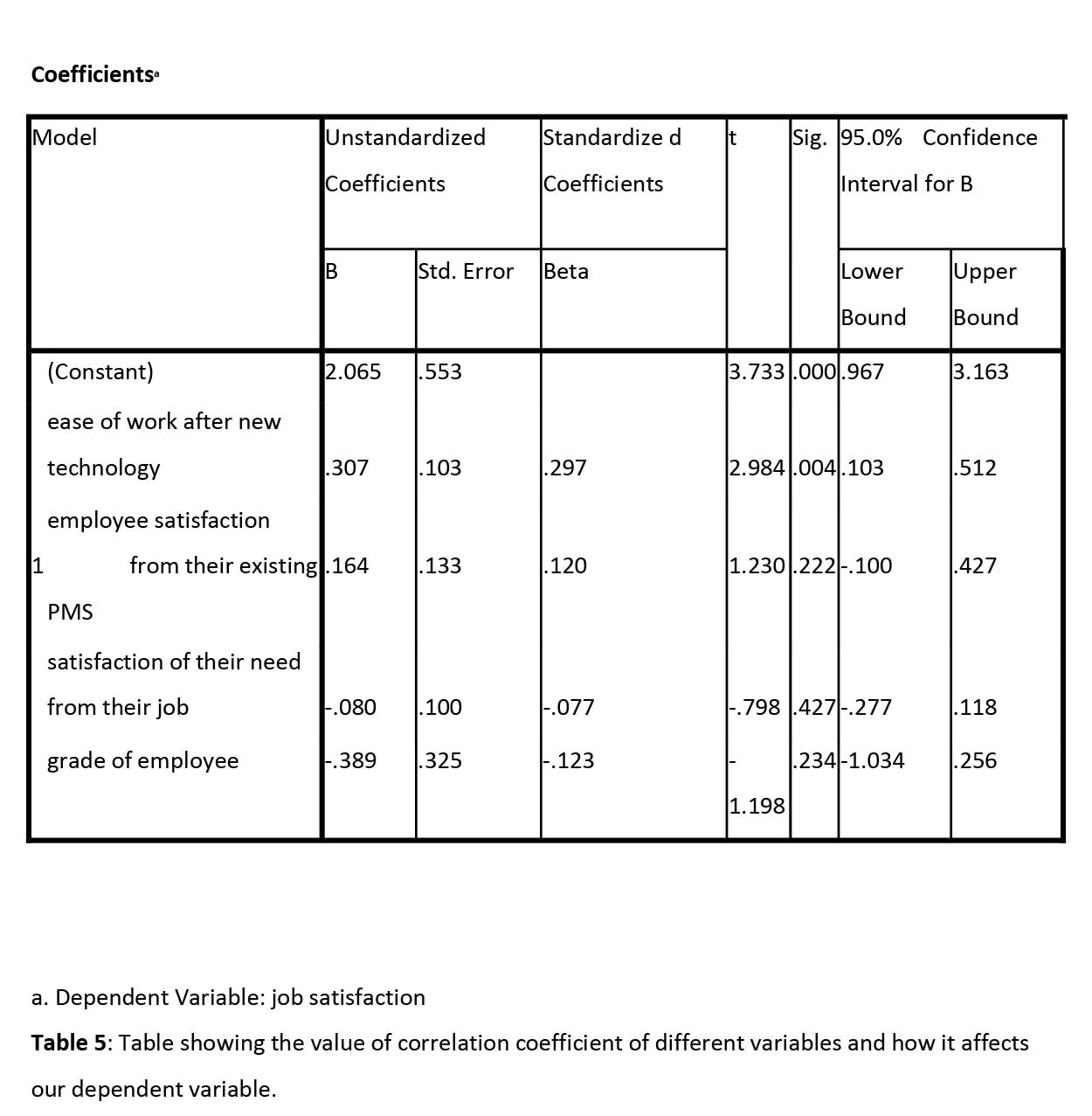

Following tables shows the result that we obtained.

6. Limitations-

The limitation of this research is that the employees were not upgraded with the newer technologies and existing PMS making them unaware of the significance of both in their job satisfaction. As, it was a government company, we can see the employees were not much aware the existing PMS of the organisation. The employees were also not aware of many schemes, policies of the organisation and government leading to their less job satisfaction.

7. Conclusion

There is a need of more training of the upcoming technologies and HR analytics applications to make their work smoother, helps in attainment of United Nations SDGs and making a better sustainable world. Coal, being a most important fossil fuel, will continue to be in greater usage till the advancement of technology and coming up of other alternative fuels. Given the existing energy crises, a better, controlled and sustainable use of coal is required. There is very less or nearly no significance of the grade of employees on the job satisfaction. The needs were satisfied by the job, but it is not the motivating factor for the employees. Many accepted the fact of improvement in the existing PMS of the employees in coal sector. With the coming of the industry 5.0, the coal industry of India also needs many improvements, making their employees feel safety in work practices, motivated by the newer PMS, machines and safety measures at work. In nut shell, we can conclude from this research that job satisfaction, being a qualitative entity, highly depends upon the factors like coming up of the technology and PMS of the organisation and less dependent on the grade and need satisfaction of the employees. This research also gives us a future prospect of working in the improvement of technology and good performance management system for the employees, which will increase the percentage of retention rate, job satisfaction, motivation level of the employee at whole.

8. References

- Jill, R. (2005). Working time, industrial relations and employment relationship, Time Society, 14(1), 89-111.

- Jou Y.T. et al. A Performance evaluation of introducing Balanced Scorecard to high-tech related industries in Taiwan, The International Journal of Applied Management and Technology, Vol 6, Num 1

- Sánchez F., Hartieb P., Innovation in the mining industry: Technological trends and a case study of the challenges of disruptive innovation, Springer, Mining, Metallurgy and Exploration (2020) 37:1385-1399, https://doi.org/10.1007/s42461-020-00262-1

- Wang B, Yang Z, Xuan J, Jiao K. Crises and opportunities in terms of energy and AI technologies during the COVID-19 pandemic. Energy and AI. 2020Aug;1:100013. doi: 10.1016/j.egyai.2020.100013. Epub 2020 Jun 5. PMCID: PMC7273151.

- Benjamin Y., People analytics in the era of big, Academia

- Nimbalkar S., Coal mines workers and motivation, David publishing, Psychology Research, March 2017, Vol. 7, No. 3, 186-204 doi:10.17265/2159- 5542/2017.03.005 (2017)

- Bozovic J., Bozovic I., Research and improvement of employee motivation in mining companies: a case study of “Ibarski Rudnici”, Serbia, IRMM, ISSN: 2146-4405 (2019)