Subscribe now to get notified about IU Jharkhand journal updates!

Analysis of Supplier’s Sustainability Indicators Influencing Satisfaction of Customers of Industrial Chemical Products

Abstract :

Sustainability, in recent times, has emerged as a significant concern across organisations, with industrial customers increasingly seeking sustainable supply chain management (SSCM) practices along with sustainable process management (SPM) to meet their environmental, social, and economic objectives. While Environment-Social-Governance (ESG) parameters are primarily responsible for the sustainability of a manufacturing firm, these firms are now using the ESG lens to analyse the performance of their suppliers. This study aims to analyse the ESG indicators of suppliers’ sustainable performance affecting customer satisfaction with selected industrial chemical products in the Indian context. From the literature survey, ESG indicators applicable to similar industries were identified as Product Stewardship, Management of Emissions (Greenhouse Gases, SOx, NOx, etc.), Water Management, Solid Waste Management, Workplace Health and Safety Management, Energy Management, Corporate Governance, and Information Security Management System, Compliance with Human Rights including Employee Well-being and Community Engagement. The significance and prioritisation of these ESG indicators were evaluated based on the perspectives of Indian customers of industrial chemical products. A case study approach was employed, collecting data through pre-tested structured questionnaires from 205 industrial customers across India. These customers represent various manufacturing sectors such as Tyres, Automotive rubber components, Lead-Acid batteries, Precipitated Silica, Power generation from Steam, and Carbon Black, procuring different chemicals as raw materials for manufacturing processes. Since the current study is involved in identifying the ESG indicators which can influence customer satisfaction for industrial chemical products, a descriptive research design has been adopted. From the results of the p-value, it is evident that all the identified ESG performance indicators are significant. As evident from the standardised regression coefficients (Beta value), the Management of emissions plays the most significant role followed by Product Stewardship in shaping customer satisfaction. Whereas, the factors that play the least significant role are Corporate Governance & Information Security Management Systems, Compliance with Human Rights including Employee Well-being and Community Engagement. The significance of other investigated factors varied among different types of customers. These findings are important for both the suppliers of industrial chemical products as they can develop action plans based on the significance and prioritisation of ESG indicators to enhance customer satisfaction.

Keywords :

Customer Satisfaction, Sustainability, Environment-Social-Governance (ESG), Industrial Chemical Products., Sustainable Process Management (SPM), Sustainable Supply Chain Management (SSCM)

- Introduction Enhancing customer satisfaction enables companies to retain their existing customers and attract new customers from the market. In the current competitive business scenario, companies need to work conscientiously to understand the stated and implied needs of current and potential customers and make all efforts to fulfil those needs for long-term business survival and growth.

- Material and methods

The current study has been conducted in two phases. Phase 1 is an initial literature survey to identify the key ESG performance indicators which apply to the manufacturers of industrial chemical products in India. Phase 2 is the verification of the significance and ranking of these identified indicators based on the data collected by administering pre-tested structured questionnaires to the customers who use these industrial chemical products at their end.

The chemical industries have been selected for this study because of the following reasons:

a) Chemical industries have a high environmental impact and their costs of environmental protection are among the highest of all industries (Christmann, 2000)

b) The business volume of the chemical industry is significantly high

2.1 Literature Review:

Rahimić (2012) described customer satisfaction as a key factor in developing and sustaining competitive advantages. Ngo, V. M. (2015) opined that customer satisfaction can play an important role in putting a higher barrier for customers against switching to other competitors.

Naumann et al. (2009) described two major benefits of customer satisfaction:

1) Satisfied customers are more likely to purchase repeatedly from a company over the longer term, which in turn increases their business volume

2) Satisfied customers are more likely to spread their positive word of mouth, which in turn will attract new customers for the company

The benefits of customer satisfaction, as mentioned by Mittal et al. (2010), are as follows; ‘it increases the expected ‘life’ of current customers, insulates customers from the competition, lowers costs of attracting new customers, reduces price elasticity (i.e., they are less likely to defect when competitors offer lower prices), lowers costs of future transactions, reduces operating costs, builds trust and reputation, a leading indicator of future economic returns’. According to Anderson et al. (2004), customer satisfaction is a central strategic concern of any business. If any business fails to satisfy its customers as effectively and efficiently as their competitors, customers will move elsewhere.

Day (1994) mentioned that companies should anticipate and respond to changing requirements of the market to get long-run competitive advantage.

Sustainability is treated as the license to do business in the twenty-first century and an integral component of this license is supply chain management (Carter et al., 2011). Govindan et al. (2014) mentioned that the objective of most of the innovations in supply chain management in the 20th century was the reduction of waste for economic reasons, whereas in the 21st century the term green, about protecting the environment, gained prominence. The lack of technology, according to the authors, is the most important obstacle to Green Supply Chain Management adoption. So, collaboration with the customers may help develop the technical expertise of the suppliers. Ahmed et al. (2022) mentioned the usefulness of aligned focus toward achieving the sustainability objectives of buyers and suppliers.

Industries are now facing pressure from government regulations, global competition, and customers on environmental initiatives (Diabat et al., 2014). Most of the big and ethical companies are now driving sustainability at the core of all their activities because of the regulatory tailwinds, investor push, and customer expectations on the adherence to sustainability criteria. According to Gualandris et al. (2015), sustainability is becoming a major concern for manufacturing firms because of the stronger social and environmental impact of their operations. Such manufacturing firms are suggested to engage in sustainable supply chain management (SSCM) practices to achieve their goal on economic, environment and social criteria (Carter and Rogers, 2008). According to Gualandris et al. (2015), SSCM is developed within a firm and has evolved from sustainable process management (SPM) to sustainable supply management (SSM). Sustainable process management refers to the sustainable practices typically within the boundary of the manufacturing firm whereas, sustainable supply management involves collaboration with the supply chain for the sustainable improved performance of the individual companies and the supply chain as a whole. While internal practices involving Total Quality Management (TQM) reduce the negative impact on the environment (Wiengarten et al., 2012), external practices are to anticipate and resolve environmental and social issues through collaboration with their suppliers, resulting in improved performance on sustainability for the implementing organization (Gualandris et al., 2014). Kumar et al. (2012) opined that SSCM may ensure a decrease in overall waste including energy, water, fuel consumption, and reduced packaging for the company.

Eccles et al. (2014) conducted a study over 18 years to compare the performance of High Sustainability firms with Low Sustainability firms in the US. According to their classification, High Sustainability firms are those who adopted long ago (by 1993) the policies guiding their impact on society and the environment including the emphasis on selection, monitoring, and evaluating the performance of their suppliers based on external environmental and social standards, while Low Sustainability firms had not adopted these policies. The finding of the study revealed that the long-term performance of High Sustainability companies is significantly higher than their counterparts, both in terms of stock market as well as financial performance. Vachon et al. (2008) mentioned that the benefits of collaborative green supply chain practices (GSCP) are the broadest with suppliers. Collaborative GSCP includes interactions between the businesses in the supply chain for setting the common environmental goal, joint environmental planning, and collaboration to reduce the negative impact on the environment. It is understood that upstream collaboration is associated with the performance related to the process, while downstream collaboration is linked with the performance related to the product.

The results of the study conducted by Hänninen, S. (2023) showed that engaging in more sustainability-focused supplier performance management is important in meeting the company’s sustainability objectives. The author mentioned Environmental performance to be measured by management of Greenhouse gas emissions, use of Resources, Waste Management, Social performance to be measured by Workplace Safety, Health and Well-being, Human Rights and diversity, Community Engagement, and Governance performance to be measured by Fair business transactions, Information security, Business continuity management.

The findings of the study conducted by Wong et al. (2012) indicate that manufacturing firms should emphasize the environmental management capability of suppliers in their green operations to get financial as well as environmental benefits.

Sustainable production, as defined by Veleva et al. (2001), is ‘the creation of goods and services using processes and systems that are non-polluting, conserving of energy and natural resources, economically viable, safe and healthful for employees, communities, and consumers, and socially and creatively rewarding for all working people’. Six major aspects of sustainable production are highlighted in the definition: use of energy and material (resources), economic performance, natural environment (sinks), workers, social justice and community development, and products. The authors highlighted some indicators applicable to the supply chain are the use of energy, use of hazardous materials, generation of waste, participation in Life Cycle Assessment(LCA) of raw material or packaging, safety training, adherence to EHS standards, adoption of ethics policy, reuse or recycle of product, product stewardship.

According to Winter et al.(2016), there is a requirement to include environmental and social criteria for the selection of supplier as well as for the evaluation of existing suppliers. These criteria include wastewater treatment and recycling, use of environment friendly raw material, management of hazardous substances, health and safety practices, prohibition child labour and forced labour, no discrimination, freedom of association, working hours, employment compensation, etc.

An analysis conducted by Susan M. Saurage-Altenloh (2017) revealed that the demonstration of Corporate Social Responsibility by the supplier influences expectation of buyer on the brand performance, which in turn increases B2B customer loyalty and results in a competitive, sustainable market advantage for such suppliers. According to the study conducted by De Mendonca et al. (2019), customer satisfaction may not be achieved by reducing the use of environmental resources relative to revenue earned. A better strategy is recycling and remanufacturing.

Bagheri et al. (2007) opined that instead of measuring sustainable development, we should look for the process indicators to establish systems for sustainable development According to Kocmanova et al. (2012), key performance indicators of ESG in the manufacturing industry are waste and hazardous waste, consumption of water, consumption of power and heat, consumption of materials and raw materials, emissions to air, accidents, odour, noise, radiation, vibration, corporate social responsibility, corporate values and code of conduct etc.

Stan et al. (2023) mentioned control of direct as well as indirect greenhouse gas emissions, the management of use of natural resources responsibly, and the comprehensive preparedness of the company for climate change, floods, and wildfires as the indicators of Environmental performance, the influence of the organization on the communities it serves, equitable remuneration and congenial working environment for workers, non-violation of fundamental Human Rights, no forced and child labour as the indicators under Social performance, whereas Corporate governance essentially involves the organization’s leadership and management philosophy, composition of boards of directors, shareholder rights.

Chvátalová et al. (2013) opined that the basic set of ESG indicators is very large. So, it is necessary to make a sensitive restriction or a suitable sorting of indicators for measuring corporate performance. Grzybowska, K. (2012) mentioned that all the enablers of sustainability in the supply chain do not require the same amount of attention. Industries need to prioritize these enablers.

According to Veleva et al. (2001), it is very difficult to have a set of common sustainability indicators which will apply to any company or organization because of the variation in the business activities of different companies.

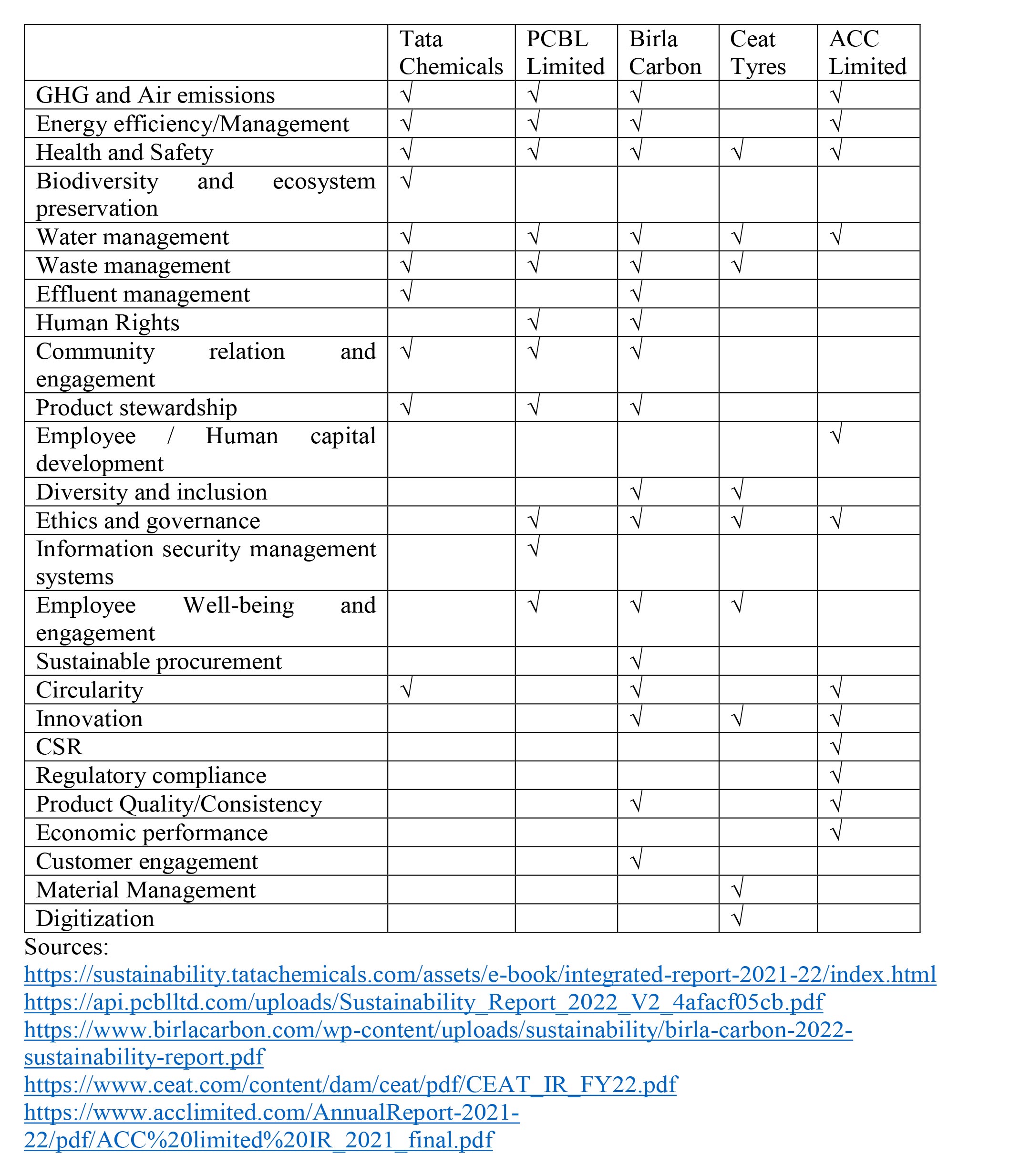

Based on the feedback from stakeholders and on the analysis of the impact of business operations on the economy, environment, and society, the key material issues (i.e. the issues that matter the most to the business) are identified by various industries as mentioned in their sustainability report available in the public domain. Key material topics, so identified by some manufacturing companies, that either produce or use industrial chemical products, are mentioned below.

Table 1.0 Key Material Topics Identified by Selected Manufacturing Companies in India

From the review of existing literature available on the subject and the experience gained by the research scholar in his professional field, the most common ESG indicators for the sustainability of manufacturers of industrial chemical products are identified as follows: Product stewardship, Management of Emissions(GHG, SOx, NOx, PM, etc.), Solid Waste Management, Workplace Health and Safety Management, Water Management, Energy Management, Compliance with Human Rights including Employee Well-being and Community Engagement, Corporate Governance and Information Security Management Systems.

From the review of existing literature available on the subject and the experience gained by the research scholar in his professional field, the most common ESG indicators for the sustainability of manufacturers of industrial chemical products are identified as follows: Product stewardship, Management of Emissions(GHG, SOx, NOx, PM, etc.), Solid Waste Management, Workplace Health and Safety Management, Water Management, Energy Management, Compliance with Human Rights including Employee Well-being and Community Engagement, Corporate Governance and Information Security Management Systems.

By Product Stewardship, we mean taking responsibility for the product from cradle to grave to reduce its impact on the environment and health. Restriction of hazardous substances (RoHS) and Substances of very high concern (SVHC) in the product are also responsibilities coming under Product Stewardship. Management of Emissions involves monitoring and controlling Green House Gas (GHG) and other emissions like SOx, NOx, PM, etc. Solid Waste Management involves a system to monitor and control the generation of hazardous and non-hazardous solid waste from the operations by means of reducing, reusing and recycling with the ultimate objective of zero waste to landfill (ZWL). Water Management involves a system to manage and monitor water consumption, reduce raw water withdrawals and wastage fulfilling the objective of zero liquid discharge (ZLD). Corporate Governance and Information Security Management System (ISMS) includes board composition with experienced and diversified members, implementation of formal ethics policies and other policies, a whistleblower procedure for the stakeholders to report deviation, ISO 27001 (or another equivalent standard) certification on information security management system etc. Compliance with Human Rights including Employee Well-being and Community Engagement ensures the protection of human rights with no incident of Discrimination at the workplace, Child Labour, Forced Labour or Involuntary Labour, Sexual Harassment, and other Human Rights related issues, procedures in place to ensure all workers are paid at least the legal minimum wage for standard working hours, weekly off, and are covered under PF, Health Insurance, Retirement and Maternity or Paternity benefits, regular community engagement programs and social impact assessments (SIA) of CSR projects undertaken by the organization. Workplace Health and Safety Management involves Hazard Identification and Risk Assessment (HIRA) for the operations and taking action to mitigate the risks, conducting safety training, capturing all the safety incidents (Near misses, Unsafe conditions, Unsafe acts, etc.), taking action to ensure zero Lost Time Injury Frequency Rate (LTIFR), ISO45001 certification on Occupational Health and Safety Management System (OHSMS), Energy Management includes monitoring and controlling energy consumption in the operations and conducting on-site energy audits, reducing the use of fossil fuel in the operations and increasing the use of energy from renewable sources.

2.2 Research Gap and Research Question:

Despite increasing attention in supplier sustainability performance, there is little evidence in existing literature on whether, and to what extent, these efforts are appreciated by customers. There is hardly any in-depth analysis on the critical ESG indicators related to suppliers’ sustainability which can influence the satisfaction of customers of industrial chemical products. The relative importance of these ESG indicators may vary from one manufacturing industry to another and also from one function to another function of the same industry, which is not found to be addressed in customer satisfaction for industrial chemical products. However, this literature survey helps in developing the background for the identification of ESG indicators that impact the sustainability of customers and suppliers of manufacturing firms. This study aims to fill this gap by addressing the following questions:

I. What are the significant or key ESG indicators related to the sustainability of manufacturers and suppliers of industrial chemical products influencing the satisfaction of their customers in India?

II. How are these key ESG indicators to be prioritized while taking action on sustainability at the supplier end?

The analysis of the significance of each of the identified ESG indicators along with their prioritisation has been done in the following sections based on the perspectives of Indian customers of industrial chemical products.

- Methodology

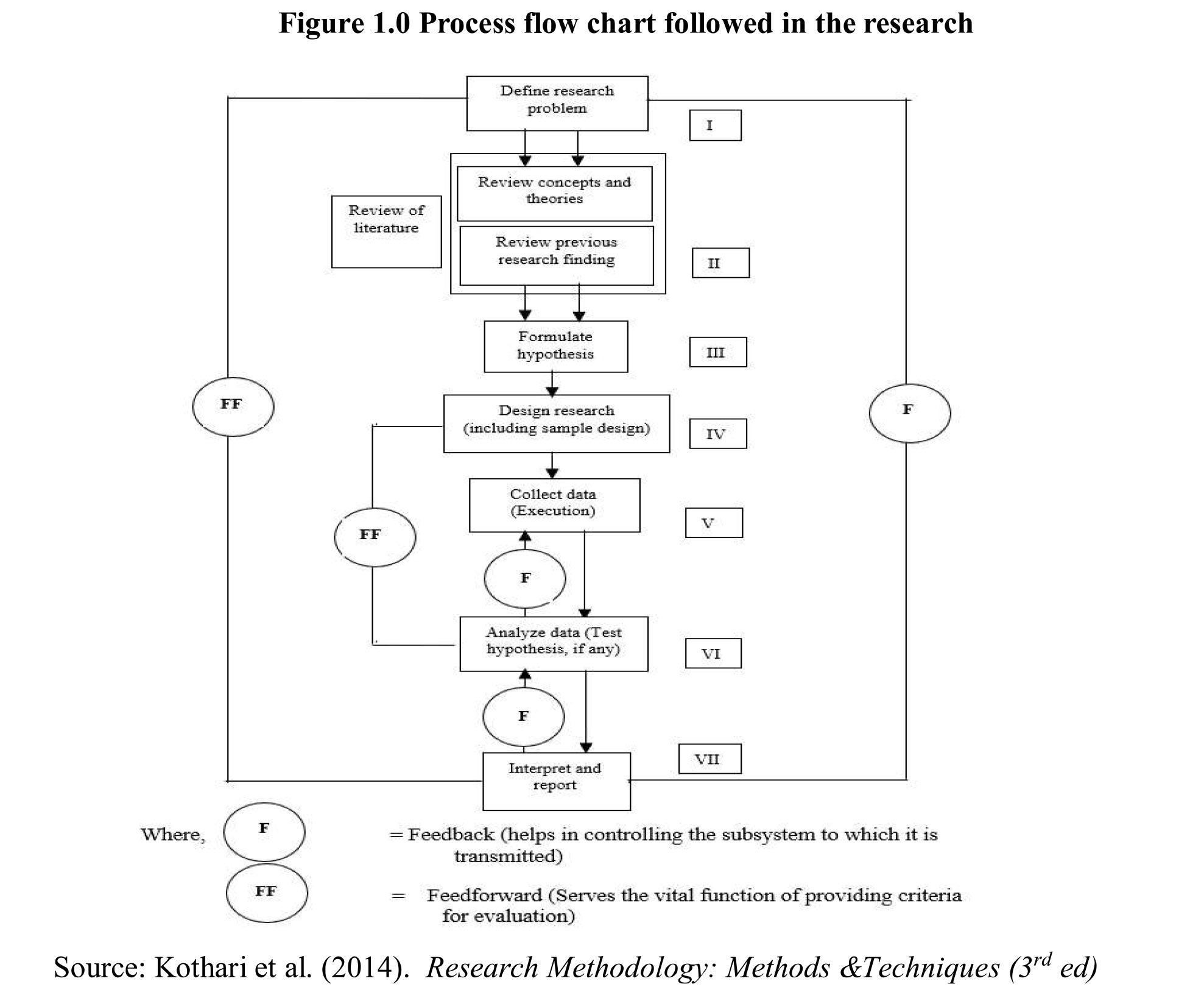

The flow chart shown in Figure 1.0 depicts the steps followed in the study.

3.1 Objective:

From the review of existing literature available on the subject and the identified research gaps following research objectives have evolved:

- To analyze the significance of identified ESG indicators related to the sustainability of manufacturers and suppliers of industrial chemical products in influencing the satisfaction of their customers in India

- To do a comparative analysis of the rankings of these ESG indicators in influencing the satisfaction of customers of different industrial chemical products

3.2 Hypotheses

To achieve the objectives mentioned in section 3.1, a set of 9 (None) hypotheses were formulated based on the eight factors identified in section 2.1 and the applicability of these factors in influencing the satisfaction of customers of selected industrial chemical products. Customer satisfaction has been considered a dependent variable. These non-directional null hypotheses were tested statistically and a conclusion was drawn from the test results.

H01: Product Stewardship of the manufacturing firm (supplier) does not have a significant role in the satisfaction of customers of selected industrial products

H02: Management of Emissions of the manufacturing firm does not have a significant role in the satisfaction of customers of selected industrial chemical products

H03: Solid Waste Management of the manufacturing firm does not have a significant role in the satisfaction of customers of selected industrial chemical products

H04: Workplace Health and Safety Management of the manufacturing firm does not have a significant role in the satisfaction of customers of selected industrial chemical products

H05: Water Management of the manufacturing firm does not have a significant role in the satisfaction of customers of selected industrial chemical products

H06: Energy Management of the manufacturing firm does not have a significant role in the satisfaction of customers of selected industrial chemical products

H07: Compliance with Human rights including Employee Well-being and Community Engagement by the manufacturing firm does not have a significant role in the satisfaction of customers of selected industrial products

H08: The Corporate Governance and Information Security Management System of the manufacturing firm does not have a significant role in the satisfaction of customers of selected industrial chemical products

H09: There is no resemblance in the rankings of identified ESG indicators in influencing the satisfaction of customers of different selected industrial chemical products

3.3 Sampling and Data Collection

To establish the significance of identified ESG indicators of manufacturers’ sustainability on the satisfaction of different industrial customers, a survey method was adopted. The instruments of data collection involved administering pre-tested structured questionnaires (Appendix A-1) either by sending questionnaires to the respondents through mail, or conducting interviews as deemed convenient. The sampling frame consisted of 205 (two hundred and five) customers from the manufacturing industries distributed across India, who procure industrial chemical products for use as raw material in their manufacturing process.

The respondents were grouped under the following three categories for the convenience of subsequent analysis.

a) Customers of Carbon Black in Tyre manufacturing companies; the total number of respondents from this group is 70 covering 16 Tyre manufacturing companies out of a total of 18 leading Tyre manufacturing companies in India that have 50 manufacturing plants which covers approx. 81% of the total population as the total number of Tyre manufacturing plants in India is 62 as per the Automotive Tyre Manufacturers’ Association (ATMA)

b) Customers of Carbon Black in Automotive Rubber Components(ARC) manufacturing companies who generally produce Industrial rubber products ( Belts, Wiper blades, Weather Strip, Rubber Hoses, Rubber Mats, Engine Mounts, Rubber Air Bags, Rubber Bumper, Bushings, Dust Cover, Mud Flaps, Rubber Pads on Pedals, O-Rings, Grommets, Seals, Gaskets, Bushings, etc.) for automobiles; the modern automobile contains about two hundred different parts made wholly or in a considerable part of rubber in which carbon black is used; the total number of respondents from this group is 70 covering 34 ARC manufacturing companies out of total 40 leading ARC manufacturing companies in India as per feedback from marketing people.

c) Customers in other industries (OIN) like manufacturers of Lead–Lead-acid batteries, Steam power plants, Precipitated Silica, and Carbon Black who procure industrial chemical products viz. Carbon Black, Sulphuric Acid, Hydrochloric Acid, Sodium Hydroxide, Zinc Oxide, Stearic Acid, Rubber Process Oil, Sulphur, Potassium Carbonate, and Potassium Nitrate for use as raw material in their manufacturing process; the number of respondents from this group is 65 covering 11 manufacturing companies in India.

Respondents were selected through a nonprobability purposive sampling method in which samples are chosen arbitrarily by the researcher based on the experience of the respondents in using industrial chemical products. The inclusion criterion of the respondents was the minimum qualification of graduation and industrial working experience of at least two years so that they are better placed to identify the factors that might have boosted their satisfaction levels and also shaped their buying behaviours. There was no restriction on the rank or designation of the respondents.

Data were collected during the period from 2021 to 2023.

Regarding the process of analyzing data, the study relied on descriptive statistics and the results were presented in the form of statistical tables, graphs, and charts. Imperative, secondary data was used from the annual report of relevant companies, trade journals, business magazines, and other publications, wherever possible to complement primary data outcomes. From an ethical perspective, the information collected was analyzed and presented in its original form without any manipulation and interference of the researcher that could have, otherwise, yielded biased outcomes. Lastly, the anonymity of the respondents, data privacy, and confidentiality were ensured by avoiding the use of the respondents’ revealing information.

- Data Analysis and Results

To understand the internal consistency between items in a scale, Cronbach’s Alpha has been measured for all the independent and dependent variables. Since all these factors resulted in a Cronbach’s alpha of 0.7 or more, these factors and their constructs can be considered reliable and therefore useful for further analysis as part of a specific variable.

As mentioned earlier, the purpose of this study was to unearth the significance of the identified ESG indicators that affect customer satisfaction for industrial chemical products. To understand the significance of each of these indicators, regression analysis has been done with the identified ESG indicators as the predictor variables and overall customer satisfaction as the dependent variable for the three cases mentioned in section 3.3.

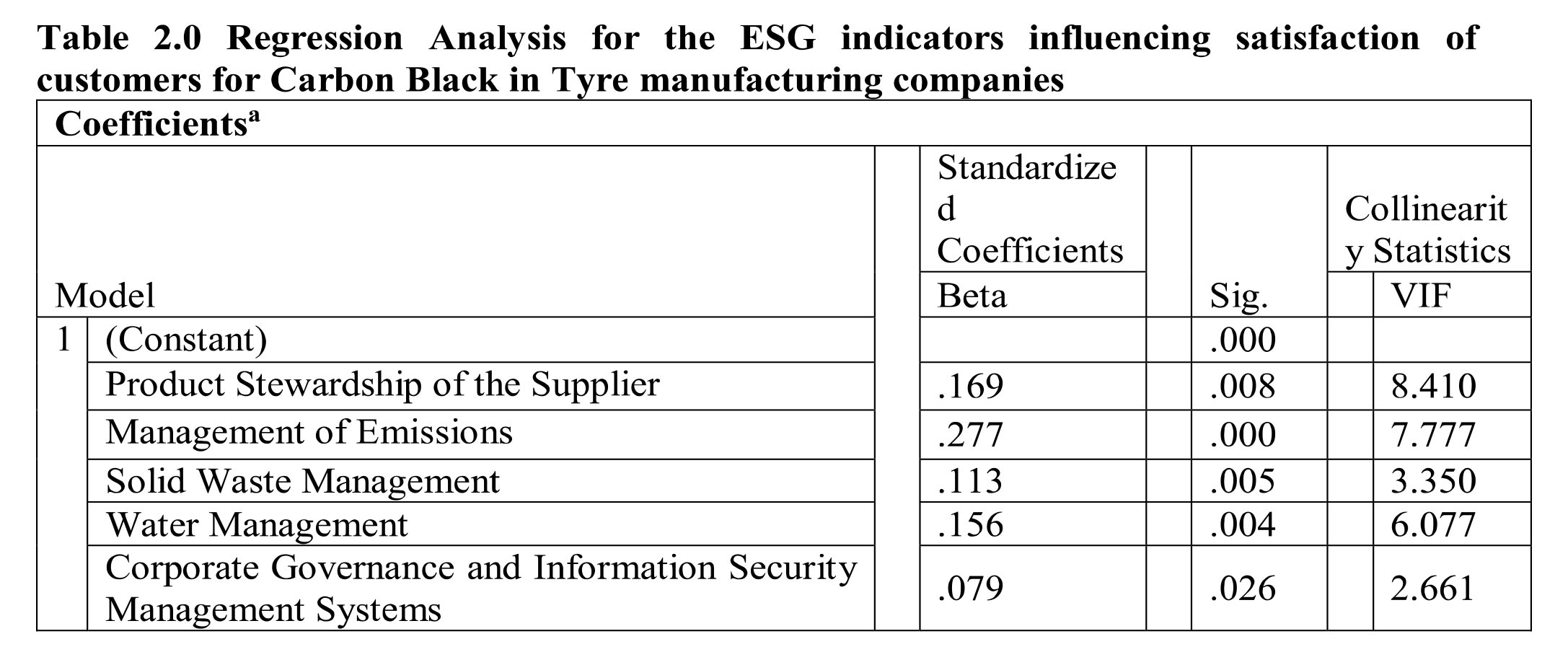

The result of regression analysis for the ESG indicators influencing satisfaction of customers for Carbon Black in Tyre manufacturing companies is shown in Table 2.0

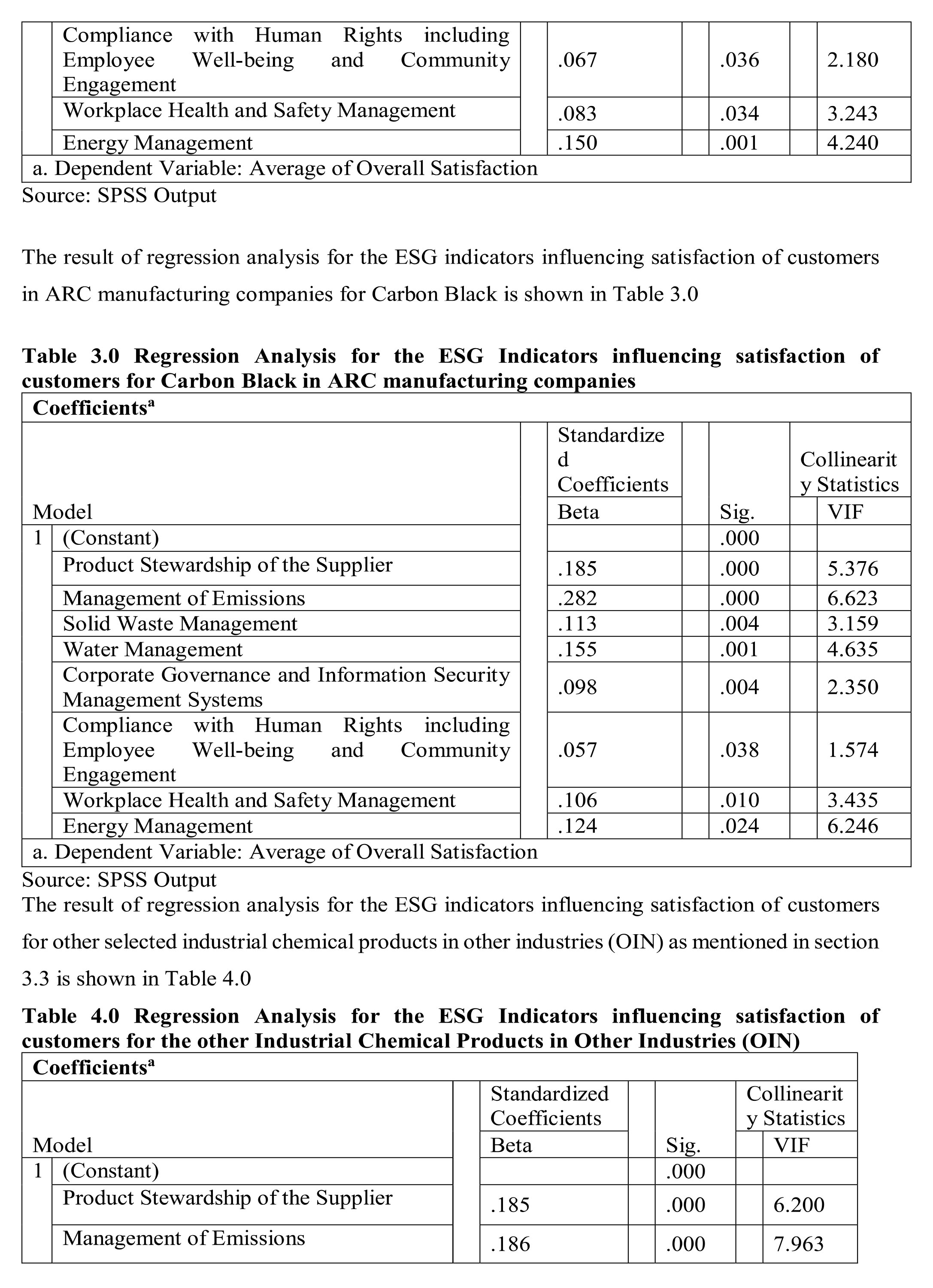

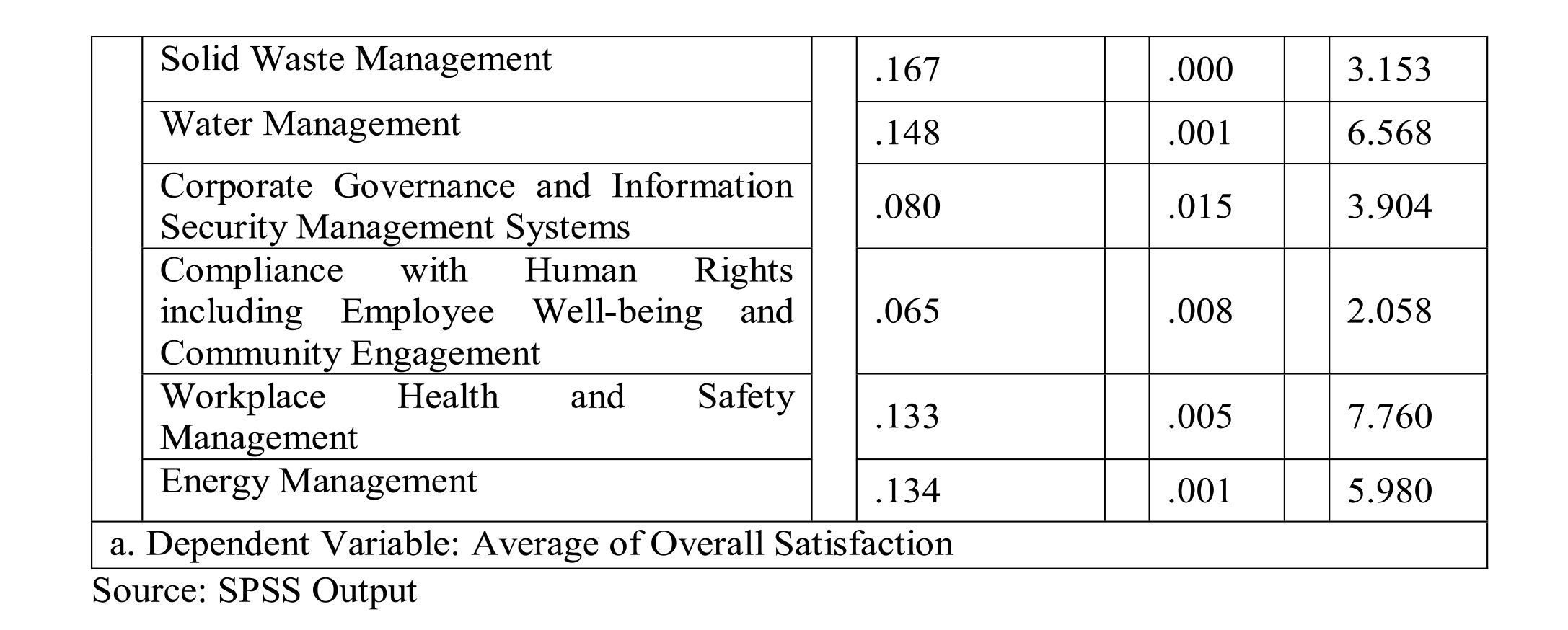

It is evident from the last column of each of Tables 2.0, 3.0, and 4.0, that all the VIF values are between 1.0 to 10.0 indicating that the co-linearity between the predictor variables is not a matter of concern in this case. It means these factors are independent and influence customer satisfaction independent of each other.

The exact significant level (p-value) is exhibited in the 3rd column (Sig.) of each of the Tables 2.0, 3.0, and 4.0. The significance level set by researches of a similar type is α = 0.050. The tables reveal that the significance levels (Sig.) for all the indicators are less than α = 0.050 in all three cases i.e. for the customers in Tyre manufacturing companies, ARC manufacturing companies, and for other selected industries (OIN) as mentioned in section 3.3.

So, the null hypotheses H01, H02, H03, H04, H05, H06, H07, and H08 as mentioned in section 3.2 are not accepted and alternative hypotheses are accepted.

That means,

- Product Stewardship of the manufacturing firm (supplier) has a significant role in the satisfaction of customers of selected industrial products

- Management of Emissions of the manufacturing firm has a significant role in the satisfaction of customers of selected industrial chemical products

- Solid Waste Management of the manufacturing firm has a significant role in the satisfaction of customers of selected industrial chemical products

- Workplace Health and Safety Management of the manufacturing firm has a significant role in the satisfaction of customers of selected industrial chemical products

- Water Management of the manufacturing firm has a significant role in the satisfaction of customers of selected industrial chemical products

- Energy Management of the manufacturing firm has a significant role in the satisfaction of customers of selected industrial chemical products

- Compliance with Human Rights including Employee Well-being and Community Engagement by the manufacturing firm has a significant role in the satisfaction of customers of selected industrial products

- Corporate Governance and Information Security Management Systems of manufacturing firms have a significant role in the satisfaction of customers of selected industrial products

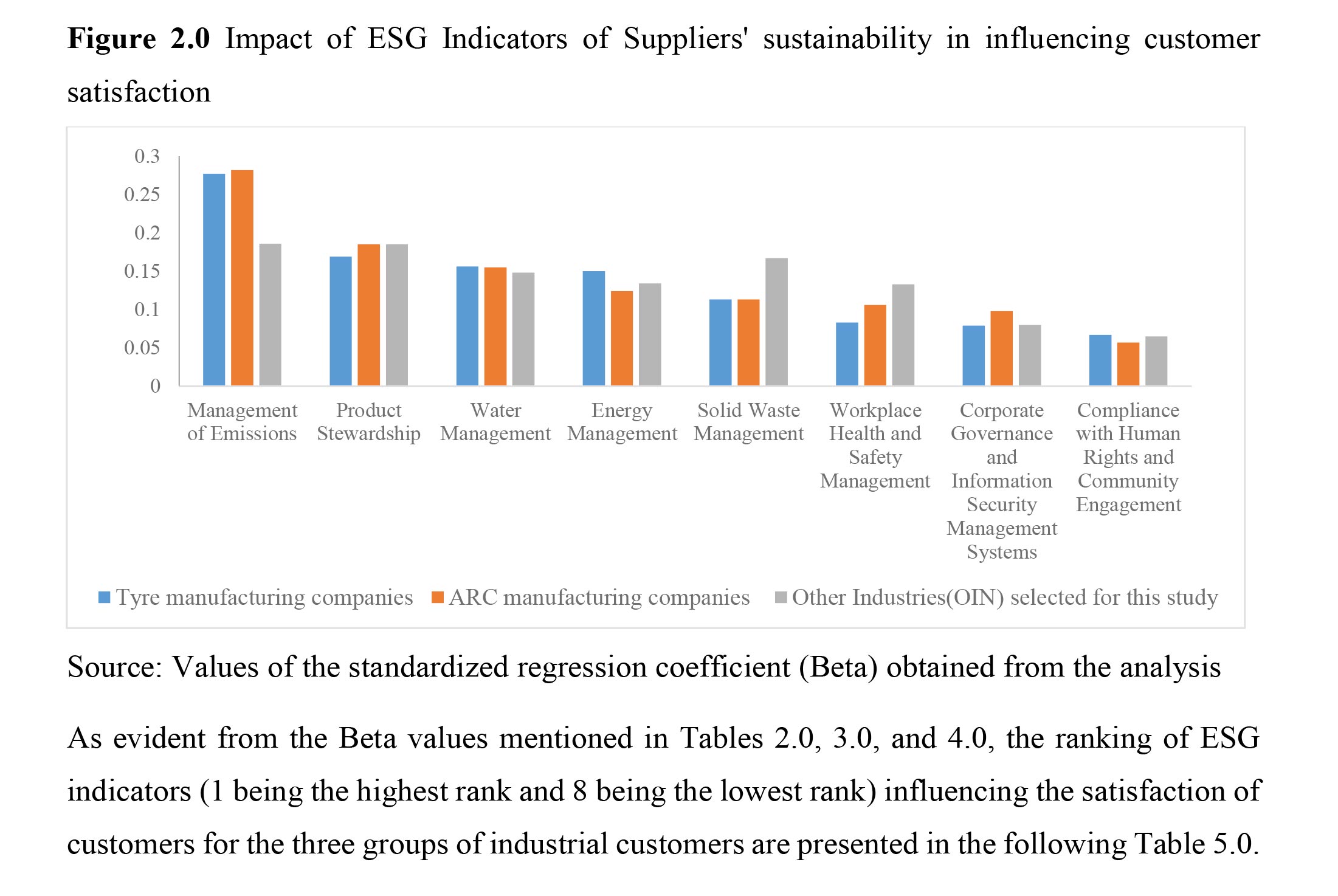

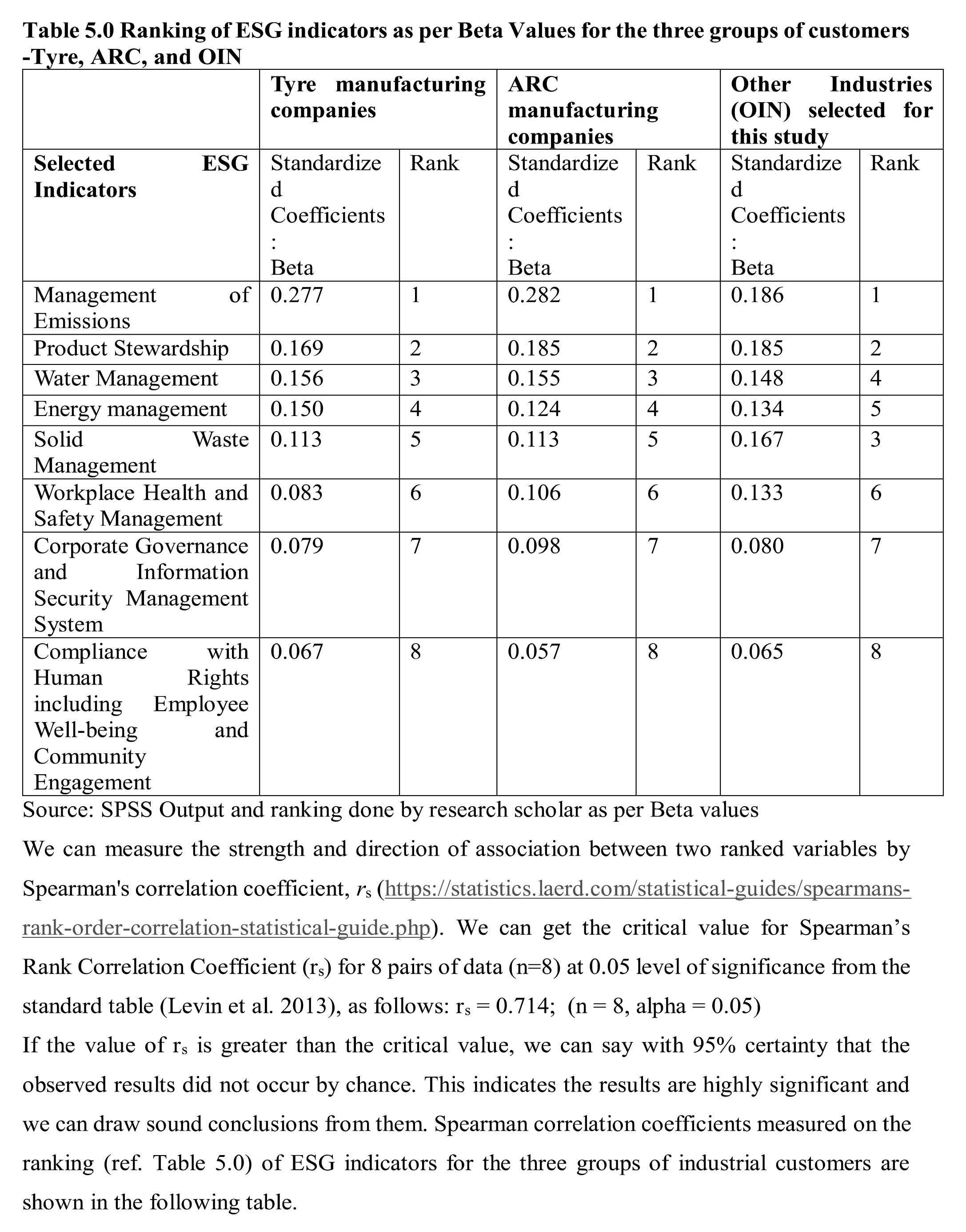

We can estimate how strongly each predictor variable influences the dependent variable from the standardized regression coefficient (Beta). The higher the Beta value, the greater the impact of the predictor variable on the dependent variable as per existing research of a similar type. The impact of ESG indicators of suppliers' sustainability in influencing customer satisfaction as evident from the values of the standardized regression coefficient (Beta) for the three groups of customers is shown in Figure 2.0.

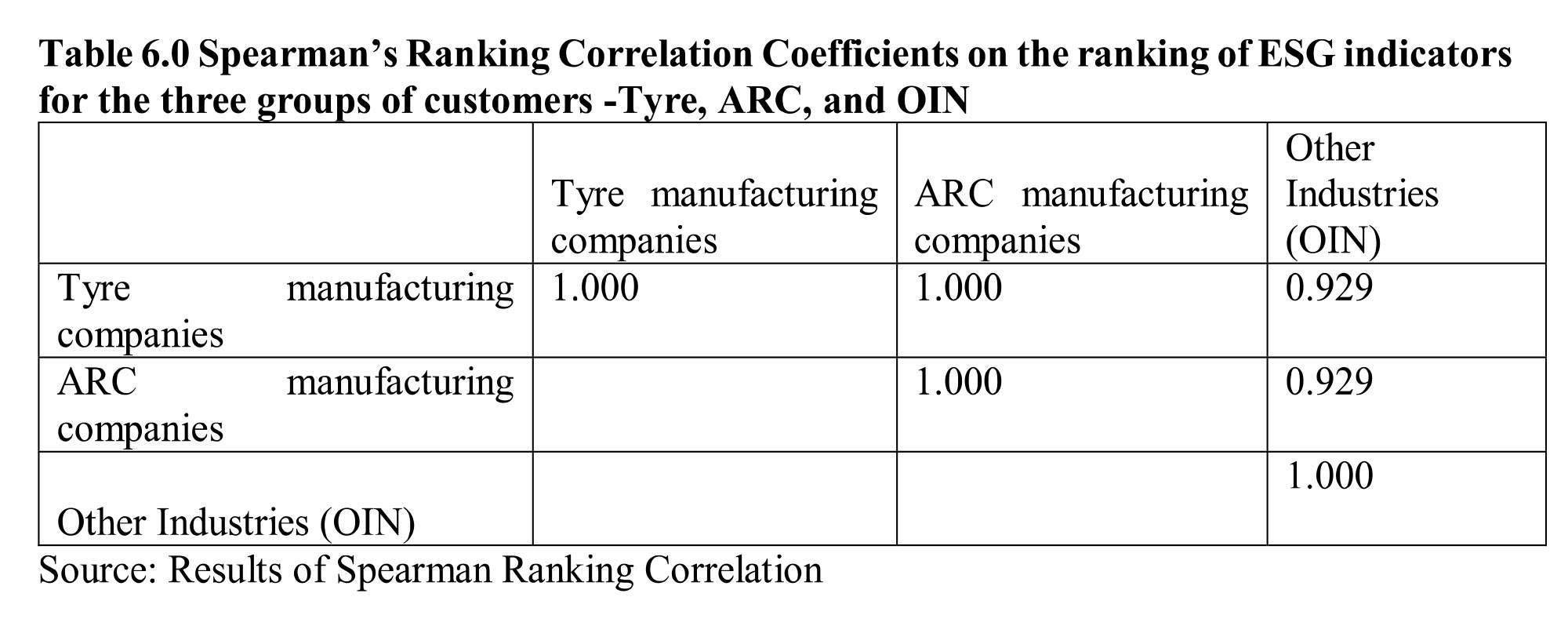

Thus, the results of the Spearman correlation, as shown in Table 6.0 indicate that

- There is a significant positive association of the ranking of ESG indicators for Tyre manufacturing companies with the ranking for ARC manufacturing companies, (rs[8]=1.000, p < 0.05) since rs is greater than the critical value of 0.714. Hence, these groups have similar perceptions relative ranking of ESG indicators for customer satisfaction.

- There is a significant positive association of the ranking of ESG indicators for Tyre manufacturing companies with the ranking for Other Industries, (rs[8]=0.929, p < 0.05), since rs is greater than the critical value of 0.714. Hence, these groups have similar perceptions relative ranking of ESG indicators for customer satisfaction.

- There is a significant positive association of the ranking of ESG indicators for ARC manufacturing companies with the ranking for Other Industries, (rs[8]=0.929, p < 0.05) since rs is greater than the critical value of 0.714. Hence, these groups have similar perception relative ranking of ESG indicators for customer satisfaction.

However, an alternative hypothesis is accepted.

That means, there is a resemblance in the prioritization of ESG indicators among customers for different industrial chemical products.

- Discussion

From the results of survey data analysis, it is observed that all the ESG indicators which are identified for the current study related to the sustainability of suppliers i.e. Product Stewardship, Management of Emissions (Greenhouse gases, SOx, NOx, etc.), Water Management, Solid Waste Management, Workplace Health and Safety Management, Energy Management, Corporate Governance, and Information Security Management Systems, Compliance with Human Rights including Employee Well-being and Community Engagement are significant in influencing satisfaction of industrial customers for carbon black in Tyre manufacturing companies and ARC manufacturing companies, and the industrial customers of other selected industrial chemical products in other industries(OIN). The significance of waste and hazardous waste, consumption of water, consumption of energy, and emissions to air, as the key performance indicators of ESG in the manufacturing industry confirms the findings of the study conducted by Kocmanova et al. (2012). The significance of the management of Greenhouse gas, and the indicators of social and human rights, corporate governance confirms the earlier observation of Stan et al. (2023).

Moreover, there is a resemblance in the prioritization of ESG indicators among the customers of different industrial chemical products as evident from the Spearman ranking correlation coefficients in Table 6.0, though the degree of impact of each of these ESG indicators on customer satisfaction is found to vary from one group of customers to another group of customers. It is observed from Table 5.0 that the ESG indicator which plays the most significant role in shaping customer satisfaction involves the Management of Emissions (Green House Gases, SOx, NOx, etc.) as per the opinion of all three groups of customers. The indicator which plays the second-most significant role in shaping customer satisfaction is product stewardship. The indicator which has the least impact on customer satisfaction is Compliance with Human Rights Employee Well-being and Community engagement.

From Table 5.0, it is observed that the two ESG indicators that play the most significant roles in shaping customer satisfaction involve the Management of emissions and Product Stewardship. The indicators that play the least significant role are Corporate Governance & Information Security Management Systems, Compliance with Human Rights Employee Well-being and Community Engagement. The degree of significance of the rest of the investigated indicators was found to vary from one group of customers to another group of customers which is consistent with the findings of earlier studies (Chvátalová et al., 2013; Grzybowska, K., 2012; Veleva et al., 2001). - Conclusions

It is evident from the results of the survey data analysis that the customers of industrial chemical products are aware of the immediate requirement of reduction in emissions (GHG etc.) which are responsible for global warming and it is reflected in the top priority given to Management of emissions. Industrial customers are very much concerned about the environmental impact of the industrial chemical product which they are procuring from their suppliers which is evident from the second higher ranking of Product Stewardship. There is no difference in prioritization of other selected ESG indicators between the customers of carbon black in Tyre manufacturing companies and the customers of carbon black in ARC manufacturing companies. Although there is some difference in the prioritization of selected ESG indicators between the customers of carbon black and the customers of other selected industrial chemical products, there is a significant positive association among the rankings of ESG indicators as per the opinion of the selected three groups of customers of industrial chemical products. The reason for the higher ranking of Water Management is quite obvious as a significant amount of water is used in various operations during the production of industrial chemical products and water scarcity is a matter of concern across the globe. A higher ranking of Energy Management may be attributed to the dependence on limited fossil fuel reserves or non-renewable sources of energy by most industries. Similarly, solid wastes (hazardous and non-hazardous) are generated during the manufacturing of various industrial products, and a major part of it is sent to landfills; inadequate control of this waste may lead to a huge environmental impact which explains the higher ranking of Solid Waste Management. It is a mandatory requirement to ensure the Health and Safety of employees for the smooth operation of the manufacturing industry which prompts the industrial customers for a higher ranking of Workplace Health and Safety Management. Corporate Governance and Information Security Management Systems, Compliance with Human Rights Employee Well-being and Community engagement are also significant criteria in influencing the satisfaction of industrial customers for carbon black in Tyre manufacturing companies and ARC manufacturing companies, and industrial customers of other selected industrial chemical products in other industries (OIN), but their rankings are lower as compared to the ranking of other ESG indicators.

6.1 Managerial implication of the study

The study revealed that all the ESG indicators identified for the study are significant and there is a resemblance in the prioritization of these ESG indicators among customers of different industrial chemical products. Thus, suppliers of industrial chemical products need to go by this prioritization and formulate action plans on these ESG indicators to satisfy their customers. This prioritization may, however, change with time, and therefore, it needs to be reviewed along with the feedback from the stakeholders at regular intervals and whenever there is a significant change in the business operations. Some of the action points as mentioned below, can primarily be implemented at the supplier end to ensure their sustainability and to satisfy their customers as well.

- Developing a robust system for the management of Green House Gas (GHG) and other emissions (SOx, NOx, etc.) and setting a carbon reduction roadmap through SBTi

- Life Cycle Assessment (LCA) of the product and reducing the impact of the product on the environment and health, estimating the proportion of hazardous substances in the product and taking action to reduce it, disclosing ecological information (toxicity, persistence, degradability, etc.) in the Safety Data Sheet of the product

- Developing a robust system of Water Management and putting emphasis on recycling and reducing consumption and wastage of water, compliance to Zero Liquid Discharge (ZLD)

- Developing a robust system of Energy Management, investing in renewable energy, and certification on ISO50001

- Developing a robust Quality Management System to reduce defects, reducing, reusing, and recycling non-biodegradable materials to manage solid waste and reducing waste to landfill

- Developing a robust system of Occupational Health and Safety Management and certification on ISO450001

- Compliance with the requirements of Human Rights and implementation of policies to prevent forced labour, child labour, discrimination, or harassment based on race, sex, colour, national or social origin, ethnicity, religion, age, disability, sexual orientation, gender identification or expression, political opinion or any other status protected by applicable law and to ensure minimum wage, weekly off, freedom of association, collective bargaining, etc.

- Engagement with the communities by conducting regular community engagement programs, taking initiative towards Corporate Social Responsibility and Social Impact Assessment(SIA)

- Developing robust governance system to ensure ethics and code of conduct including anti-bribery and anti-corruption, grievance redressal mechanism, avoidance of conflict of interest, competition, stakeholder engagement, board composition to ensure there are executive, non-executive, and independent directors, board diversity, board committees for audit, risk management, CSR, etc., timely disclosure of the actions taken and results achieved on ESG objectives in third party assessed sustainability report

- Robust Information Security Management Systems and certification on ISO 270001

- Developing a robust system of environmental management and certification on ISO14001

- Identifying and mitigating long-term Environmental, Social, and Governance (ESG) risks

As mentioned in section 2.2, there is inadequate analysis of the critical ESG indicators related to suppliers’ sustainability which can influence the satisfaction of customers of industrial chemical products. The findings of the current study provide the following key insights which contribute to the existing body of knowledge. In the current study, the significant ESG indicators of sustainability of the manufacturers and suppliers of industrial chemical products have been identified. As mentioned in section 4.0, the management of waste and hazardous waste, water, energy, and emissions to air are significant performance indicators of the sustainability of the manufacturing industry which confirms the findings of the study conducted by Kocmanova et al. (2012). The significance of the management of Greenhouse gas emissions, compliance with social and human rights, and robust corporate governance are aligned with the earlier observation of Stan et al. (2023). The degree of significance of the rest of the investigated indicators, as established in the current study, varies from one group of customers to another group of customers which supports the findings of the earlier studies (Chvátalová et al., 2013; Grzybowska, K., 2012; Veleva et al., 2001). Sustainability is now gaining prominence across the globe and sustainability indicators may be an important consideration in subsequent research as it gains more importance and is understood from the right perspective, especially for the manufacturers and suppliers of industrial chemical products.

6.3 Limitations and future scope of study

This study has some limitations subject to systematic and random error which can be taken into consideration when interpreting its findings and conducting further research.

- As the current study is of cross-sectional type involving the collection of data at a specific point of time (from the year 2021 to 2023), it is difficult to establish a fundamental relationship between the variables; a longitudinal study can also be conducted over several periods for assessing how the relative importance of the ESG indicators change over time

- Another limitation of the current study is that the sample was drawn from India only; future studies can be extended to more diverse settings i.e. in other countries for generalization of our finding

- The respondents in the current study were selected from the customer end only; future studies may be conducted by selecting the respondents from both suppliers’ organization and customers’ organization

- In the current study, industries related to industrial chemical products were only considered; in the future, the study could be replicated in different industries to complement this study and to provide more insight into enablers

- Different ESG indicators influencing the satisfaction of customers were considered holistically and in doing so, some of the major aspects of each of these indicators might have been missed which can be considered in future study

In the business-to-business (B2B) market, transactions happen when one company purchases products from another manufacturer and uses them in the production of other products in their industry. Such industries include manufacturing, construction, agriculture, communication, transportation, etc. Typically, purchase decisions are taken based on product specifications, preferred supplier lists, and performance reviews on cost and efficiency. The chemical industry is one of the most important contributors to the economy of a country. Industrial chemicals are used either as raw materials in the production processes of the manufacturing industry or as ingredients in commercial consumer products. The range of industrial chemicals is broad and includes fillers, lubricants, solvents, mastics, coatings, dyes, colourants, reactants, inks, stabilizers, plasticizers, fragrances, flame retardants, conductors, and insulators. These chemicals are indispensable for industrial production and greatly support our daily life. The diversified chemical industry of India is classified broadly into petrochemicals, agrochemicals, bulk chemicals, specialty chemicals, fertilizers and polymers. As per the All India Association of Industries (https://aiaiindia.com), ‘the Indian chemicals industry with more than 80,000 commercial products, stood at US$ 178 billion in 2019 and is expected to grow at a CAGR of 9.3% to reach US$ 304 billion by 2025’ (https://aiaiindia.com/chemicals/#:~:text=The%20Indian%20chemicals%20industry%20stood,to%20India's%20GDP%20by%202025).

Factors influencing customer satisfaction in the Business-to-Business (B2B) context that have attracted scholarly interest include price, product-specific factors, dependability of the supply, customer relationship, value-added services, product development, brand image, etc. Customers are now monitoring the performance of their suppliers in terms of ESG indicators. According to Lee et al.(2024), ESG management plays a crucial role in sustainable corporate performance.

Disruption in the usual balance of nature with the growth of human civilization has resulted in global warming and loss of biodiversity. It is quite evident that Earth’s ecosystem cannot be maintained if more sustainable choices are not made. If the manufacturing companies continue to run harmful processes with no change, it is inevitable fossil fuel will be completely exhausted, and a huge number of animal species will become extinct with permanent damage to the atmosphere. As notified by Climate Action Tracker (Climate Action Tracker - Wikipedia) on 9 November 2021, ‘the global temperature will rise by 2.7 °C by the end of the century with current policies and the temperature will rise by 2.4 °C if only the pledges for 2030 are implemented, and by 1.8 °C if all the announced targets are fully achieved’. In COP26 held on 13 November 2021, the participating 197 countries agreed on the Glasgow Climate Pact, aimed at staving off dangerous climate change (Climate change - Wikipedia). The pact reaffirmed the validity of the Paris Agreement to ‘hold the increase in the global average temperature to well below 2 °C above pre-industrial levels and pursuing efforts to limit the temperature increase to 1.5 °C above pre-industrial levels’. At COP26, the Government of India also expressed the concerns of developing countries to the United Nations Framework Convention on Climate Change (UNFCCC). As per Ministry of Environment, Forest and Climate Change, ‘India presented the following five nectar elements (Panchamrit) of India’s climate action: a) Reach 500GW non-fossil energy capacity by 2030, b) 50 per cent of its energy requirements from renewable energy by 2030, c) Reduction of total projected carbon emissions by one billion tonnes from 2021 to 2030, d) Reduction of the carbon intensity of the economy by 45 per cent by 2030, over 2005 levels, e) Achieving the target of net zero emissions by 2070’.

With the increasing concern of global warming and the resulting melting of ice, rise in sea level, Ozone depletion, and loss of biodiversity, companies have now understood they must focus on sustainability and maintain a proper balance among Planet, People, and Profit, as their stakeholders want to be associated with future-ready organizations.

By ‘Sustainability’, we mean the ability to sustain. As defined by the UN’s Brundtland Commission sustainability is ‘meeting the needs of the present without compromising the ability of future generations to meet their own needs’. The term Sustainability is used to describe many green concepts and corporate responsibility. ESG has now become the preferred term for many investors and the capital markets. ESG, an acronym for Environment, Social, and Governance, is a framework for assessing the impact of the sustainability and ethical practices of a Company. Companies performing well in ESG-related matters and demonstrating transparency are eligible to achieve higher ESG ratings which in turn will provide better access to funding as well as more favorable financing terms. Good performance in Sustainability improves reputation and brand image.

The major performance indicators towards Environmental protection are Greenhouse Gas emissions and removal from the atmosphere, air emissions (SOx, NOx, Particulate matter etc.), usage of energy, raw water usage, waste to landfill, usage of raw materials and packaging materials, and transportation. Similarly, the performance indicators of Social growth are Health and Safety, prevention of forced labour and child labour, discrimination, harassment, and abuse, and ensuring freedom of association, collective bargaining, appropriate compensation, and hours of work as per regulatory requirements. The performance indicators of robust Governance are accountability, grievance redressal, and stakeholder engagement.

Supplier Sustainability is recognized as a significant contributor to the sustainability of a manufacturing company (Gualandris et al., 2016) and so, customers are now using the ESG lens to analyze the performance of their suppliers.

According to Gualandris et al. (2016), sustainability performance, indicated by environmental and social (E and S) performance, can be improved by internal and external practices of an organization. Internal practices are reflected in the sustainability of the manufacturing firm. External practices are fully impacted by the sustainability performance of the key suppliers of manufacturing firms. Sustainable procurement can ensure a reduction in the environmental impact of the product bought.

Ahmed, M. U., & Shafiq, A. (2022). Toward sustainable supply chains: Impact of buyer's legitimacy, power and aligned focus on supplier sustainability performance. International Journal of Operations and Production Management, 42(3), 280–303. https://doi.org/10.1108/IJOPM-08-2021-0540

Anderson, E. W., Fornell, C., & Mazvancheryl, S. K. (2004). Customer satisfaction and shareholder value. Journal of Marketing, 68(4), 172–185. https://doi.org/10.1509/jmkg.68.4.172.42723

Bagheri, A., & Hjorth, P. (2007). A framework for process indicators to monitor for sustainable development: Practice to an urban water system. Environment, Development and Sustainability, 9(2), 143–161. https://doi.org/10.1007/s10668-005-9009-0

Carter, C. R., & Liane Easton, P. (2011). Sustainable supply chain management: Evolution and future directions. International Journal of Physical Distribution & Logistics Management, 41(1), 46–62. https://doi.org/10.1108/09600031111101420

Carter, C. R., & Rogers, D. S. (2008). A framework of sustainable supply chain management: Moving toward new theory. International Journal of Physical Distribution & Logistics Management, 38(5), 360–387. https://doi.org/10.1108/09600030810882816

Christmann, P. (2000). Effects of “best practices” of environmental management on cost advantage: The role of complementary assets. Academy of Management Journal, 43(4), 663–680. https://doi.org/10.2307/1556360

Chvátalová, Z., & Šimberová, I. (2013). Analysis of ESG indicators for measuring enterprise performance. Acta Universitatis Agriculturae et Silviculturae Mendelianae Brunensis, 61(7), 2197–2204. https://doi.org/10.11118/actaun201361072197

Day, G. S. (1994). The capabilities of market-driven organizations. Journal of Marketing, 58(4), 37–52. https://doi.org/10.1177/002224299405800404

De Mendonca, T. R., & Zhou, Y. (2019). Environmental performance, customer satisfaction, and profitability: A study among large US companies. Sustainability, 11(19), 5418. https://doi.org/10.3390/su11195418

Diabat, A., Kannan, D., & Mathiyazhagan, K. (2014). Analysis of enablers for implementation of sustainable supply chain management–A textile case. Journal of Cleaner Production, 83, 391–403. https://doi.org/10.1016/j.jclepro.2014.06.081

Dufvelin, H.(2018), Determining key performance indicators for environmental, social and governance [Master’s Thesis].Lappeenranta University of Technology.

Eccles, R. G., Ioannou, I., & Serafeim, G. (2014). The impact of corporate sustainability on organizational processes and performance. Management Science, 60(11), 2835–2857. https://doi.org/10.1287/mnsc.2014.1984

Govindan, K., Kaliyan, M., Kannan, D., & Haq, A. N. (2014). Barriers analysis for green supply chain management implementation in Indian industries using analytic hierarchy process. International Journal of Production Economics, 147, 555–568. https://doi.org/10.1016/j.ijpe.2013.08.018

Grzybowska, K. (2012). Sustainability in the supply chain: Analysing the enablers. In P. Golinska & C. Romano (Eds.), Environmental issues in supply chain management. EcoProduction (pp.25–40). Springer. https://doi.org/10.1007/978-3-642-23562-7_2

Gualandris, J., & Kalchschmidt, M. (2016). Developing environmental and social performance: The role of suppliers’ sustainability and buyer–supplier trust. International Journal of Production Research, 54(8), 2470–2486. https://doi.org/10.1080/00207543.2015.1106018

Gualandris, J., Golini, R., & Kalchschmidt, M. (2014). Do supply management and global sourcing matter for firm sustainability performance? [An international study]. Supply Chain Management, 19(3), 258–274. https://doi.org/10.1108/SCM-11-2013-0430

Hänninen, S. (2023). Aligning supplier performance management with sustainable business strategy: Integrating CSR factors into supplier scorecards and performance management. https://urn.fi/URN:NBN:fi-fe20231031141979 [Master's Thesis]. LUT University.

Kocmanova, A., Nemecek, P., & Docekalova, M. (2012). Environmental, social, and governance (ESG) key performance indicators for sustainable reporting. In The 7th International Scientific Conference (pp. 655–662). https://doi.org/10.3846/bm.2012.085

Kumar, S., Teichman, S., & Timpernagel, T. (2012). A green supply chain is a requirement for profitability. International Journal of Production Research, 50(5), 1278–1296. https://doi.org/10.1080/00207543.2011.571924

Lee, S., & Kim, Y. J. (2024). Analyzing Factors That Affect Korean B2B Companies’ Sustainable Performance. Sustainability, 16(5), 1719.

Levin,R.I., Rubin,D.S., Rastogi, S., & Siddiqui, M.H.(2013).Statics for management(7th ed).

Mittal, V., & Frennea, C. (2010). Customer satisfaction: A strategic review and guidelines for managers. MSI Fast Forward Series, Marketing Science Institute. https://ssrn.com/abstract=2345469

Naumann, E., Williams, P., & Khan, M. S. (2009). Customer satisfaction and loyalty in B2B services: Directions for future research. Marketing Review, 9(4), 319–333. https://doi.org/10.1362/146934709X479908

Ngo, V. M. (2015). Measuring customer satisfaction: A literature review. In Proceedings of the 7th International Scientific Conference Finance and Performance of Firms in Science. Education and Practice, 1637–1654.

Rahimić, Z., & Uštović, K. (2012). Customer satisfaction as a key factor in building and maintaining competitive advantages of companies. Problems of Management in the 21st Century, 3(1), 91–105. https://doi.org/10.33225/pmc/12.03.91

Saurage-Altenloh, S. M. (2017). The measured influence of supplier CSR on brand performance expectations in B2B relationships ([Doctoral Dissertation]. Capella University).

Stan, S. E., Țîțu, M. A., Mănescu, G., Ilie, F. V., & Rusu, M. L. (2023). Measuring supply chain performance from ESG perspective. In International conference KNOWLEDGE-BASED ORGANIZATION,29(1),180–189. https://doi.org/10.2478/kbo-2023-0026

Vachon, S., & Klassen, R. D. (2008). Environmental management and manufacturing performance: The role of collaboration in the supply chain. International Journal of Production Economics, 111(2), 299–315

Veleva, V., & Ellenbecker, M. (2001). Indicators of sustainable production: Framework and methodology. Journal of Cleaner Production, 9(6), 519–549. https://doi.org/10.1016/S0959-6526(01)00010-5

Wiengarten, F., & Pagell, M. (2012). The importance of quality management for the success of environmental management initiatives. International Journal of Production Economics, 140(1), 407–415. https://doi.org/10.1016/j.ijpe.2012.06.024

Winter, S., & Lasch, R. (2016). Environmental and social criteria in supplier evaluation–Lessons from the fashion and apparel industry. Journal of Cleaner Production, 139, 175–190. https://doi.org/10.1016/j.jclepro.2016.07.201

Wong, C. W., Lai, K. H., Shang, K. C., Lu, C. S., & Leung, T. K. P. (2012). Green operations and the moderating role of environmental management capability of suppliers on manufacturing firm performance. International Journal of Production Economics, 140(1), 283–294. https://doi.org/10.1016/j.ijpe.2011.08.031